|

市场调查报告书

商品编码

1640375

中国工厂自动化与工业控制:市场占有率分析、产业趋势与统计、成长预测(2025-2030)China Factory Automation And Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

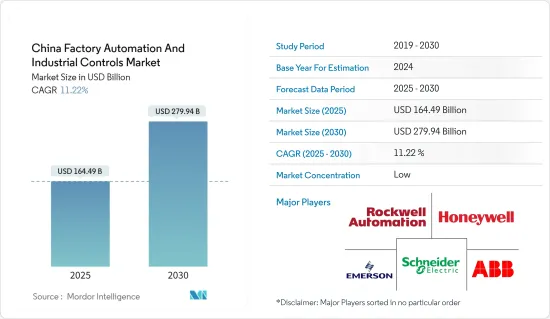

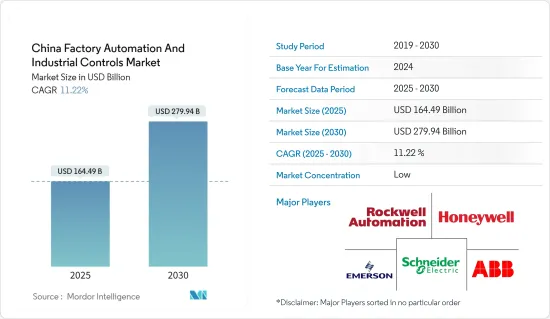

预计2025年中国工厂自动化和工业控制市场规模为1,644.9亿美元,2030年将达2,799.4亿美元,预测期间(2025-2030年)复合年增长率为11.22%。

主要亮点

- 各种製造设备的技术进步和创新正在推动自动化技术的采用。

- 中国的数位化和工业 4.0倡议极大地刺激了各行业自动化的发展,需要更多创新和自动化解决方案(例如机器人和控制系统)来改善生产流程。由于其製造能力和政府对工厂、基础设施和机械的投资,中国经济经历了令人瞩目的成长。

- 中国在工业机器人市场上处于领先地位,并推动了该地区的工厂自动化之路。该国也是亚太地区世界领先的製造业国家之一。国内工业机器人出货量的增加以及各种工业控制系统软体在全国范围内的采用正在推动大规模工厂自动化。

- 随着智慧製造的引入,中国自动化可望拓展智慧化。据工业信部介绍,过去几年,我国已启动了100多个智慧生产先导计画。此外,2022年6月,深圳市发表了《智慧机器人产业丛集培育发展行动计画》。 2023年6月,北京市政府公布了《北京市机器人产业创新发展行动计画(2023-2025年)》。

- 政府的奖励和目标提高了中国市场进入工厂自动化的潜力。 《中国製造2025》计画鼓励国内参与企业减少对外国参与企业的依赖。中国人事费用的快速上升和製造业劳动力供应的下降也推动了工业机器人和工厂自动化的普及。

- 政府对采购计画的大力支持也支持向工业 4.0 的过渡。例如,中国工业机器人製造商新鬆与中国科学院合作,中国科学院又与政府合作。

- 随着中国生产成本上升以及人民币兑美元走强,投资者将注意力转向生产所在地。然而,製造商应关注高品质生产和环保製造法规。随着技术的发展,完全自动化的设施需要数年时间来调整和发展。另一方面,由于主动自动化适应方面的不利或延迟努力,以地区为基础上的成长受到限制。

中国工厂自动化与工业控制市场趋势

分散式控制系统领域预计将占据主要市场占有率

- DCS 是一个以流程为导向的平台,依靠互连的感测器、控制器、终端和致动器作为设施生产营运的集中主控制器。因此,DCS着重于製程控制和监控,使设备操作员能够从一个位置查看所有设备的运作情况。

- DCS 系统的主要优点之一是分散式控制器、工作站和其他运算元件之间的数位通讯遵循P2P存取的原则。在石化、核能工业、石油和天然气工业等製程工业中,对控制器的需求不断增加,这些控制器可以在指定的设定点附近提供指定的製程公差,以实现更高的精度和控制。

- 此外,许多需求正在推动 DCS 的采用。这些系统降低了操作复杂性、计划风险,并提供了诸如在要求苛刻的应用中实现敏捷製造的灵活性等功能。 DCS 整合各种工厂製程控制(例如 PLC、涡轮机械控制、安全系统、第三方控制、热交换器、给水加热器和水质)的能力进一步推动了 DCS 在能源领域的采用。

- 中国发电的发展正在推动对分散式控制系统(DCS)的需求。根据中电联发布的《2023年全国消费性电子电力产业统计资料》,2023年我国发电总装置容量为2919.6吉瓦。

- 2022年1月,中国宣布采用双控系统控制能源消耗。未来,能源消费量和基本单位将转变为二氧化碳排放和电力的「双控系统」。这些努力预计将在 2024 年至 2029 年间加速主要製造工厂采用 DCS 系统。

石油和天然气产业预计将大幅成长

- 石油和天然气平台地理位置分散,需要适当的通讯系统。 PLC、SCADA、DCS、安全自动化等解决方案的发展得益于中国庞大的工业发展。我们也预期对自动化产品(包括 DCS 系统)的大规模需求。

- 2023年3月,沙乌地阿美签署最终协议,以246亿元人民币(36亿美元)收购深圳上市公司熔盛石化10%的股权。根据该策略协议,阿美公司将向熔盛集团的子公司浙江石化每天供应48万桶阿拉伯原油,作为与该公司正在进行的长期销售协议的一部分。

- 此外,石油和天然气产业也受到有关安全、工厂可靠性和效率的多项政府法规的约束。 ICS应用于远端终端单元(RTU)以及泵站和压缩站以确保安全。

- 业界越来越多地采用 ICS 解决方案,以在不影响生产效率的情况下保持安全和环境完整性。自动化有助于整合资讯和控制、电力和安全解决方案,以满足负担得起的能源和严格的政府法规的要求。

- 此外,由于石油和天然气行业对自动化的高需求,Seeq 正在为其 CygNet 企业监控和资料采集 (SCADA) WellSite 资讯传输标记语言 (WITSML)资料存储系统引入新的连接器,并扩大了我们的支援范围。这使得在当今充满挑战的工业环境中能够进行高阶分析和资料驱动的决策。

- 近年来,石油和燃气公司在网路安全技术上投入了大量资金,包括事件回应解决方案和软体,可以从ICS环境中收集日誌,提高网路可见度和分段,以及行动和消除直接威胁。

- 各行业越来越多地采用 ICS 解决方案,以在不影响生产效率的情况下保持安全和环境完整性。自动化有助于整合资讯和控制、电力和安全解决方案,以满足负担得起的能源和严格的政府法规的要求。

中国工厂自动化与工业控制产业概况

中国的工厂自动化和工业控制市场高度细分,拥有多家知名企业。公司不断投资于策略伙伴关係和产品开发,以获得市场占有率。我们将介绍一些最近的市场发展趋势。

- 2024 年 3 月 - 罗克韦尔自动化宣布与 Nvidia 合作,加速下一代工业架构的发展。为了帮助自动化客户实现工业流程数位化,罗克韦尔计划透过建造未来工厂来推动产业发展。

- 2024 年 2 月 - ABB 宣布计划在汽车、消费品、教育、医疗保健、零售和新能源等新兴领域利用人工智慧和机器人技术的整合。这项策略性倡议旨在透过为中国各地的机器人应用引入新的自主水平,为客户创造更多价值。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

第五章市场动态

- 市场驱动因素

- 由于工作人口减少,自动化技术兴起

- 市场问题

- 行业法规政策

第六章 市场细分

- 按类型

- 工业控制系统

- 集散控制系统(DCS)

- PLC(可程式逻辑控制器)

- SCADA(监控/资料采集)

- 产品生命週期管理 (PLM)

- 人机介面 (HMI)

- 製造执行系统(MES)

- 企业资源规划系统(ERP)

- 其他工业控制系统

- 现场设备

- 感测器和发射器

- 马达和驱动器

- 工业机器人

- 机器视觉系统

- 其他现场设备

- 工业控制系统

- 按最终用户产业

- 石油和天然气

- 化学/石化

- 电力/公共产业

- 汽车/交通

- 药品

- 饮食

- 其他的

第七章 竞争格局

- 公司简介

- General Electric Company

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

第八章投资分析

第9章市场的未来

简介目录

Product Code: 52079

The China Factory Automation And Industrial Controls Market size is estimated at USD 164.49 billion in 2025, and is expected to reach USD 279.94 billion by 2030, at a CAGR of 11.22% during the forecast period (2025-2030).

Key Highlights

- The evolution of technological advancements and innovations across various manufacturing units has encouraged the adoption of automation technologies.

- Digitization and Industry 4.0 initiatives in China have significantly stimulated the growth of automation among industries by necessitating more innovative and automated solutions, such as robotics and control systems, to improve production processes. China's economy witnessed impressive growth due to its manufacturing capabilities and the government's investments in factories, infrastructure, and machinery.

- China has led the industrial robot market, driving its way to factory automation in the region. The country is also one of the leading manufacturing countries globally in Asia-Pacific. The increase in the shipment of industrial robots in the country and the adoption of various industrial control system software across the country facilitates factory automation at scale.

- Automation in China is expected to be augmented by the uptake of intelligent manufacturing. According to the Ministry of Industry and Information Technology, the country has initiated over 100 pilot projects for intellectual manufacturing in the past few years. Also, in June 2022, Shenzhen announced the Action Plan for Cultivating and Developing Intelligent Robot Industry Clusters. In June 2023, the Beijing Municipal government announced the Beijing Robot Industry Innovation and Development Action Plan (2023-2025).

- Government incentives and targets have advanced the potential of the Chinese market to dive into factory automation. Made in China 2025 plan encourages domestic players to decrease their dependency on foreign players. The rapidly soaring labor costs and declining manufacturing labor force supply in China are also helping in the penetration of industrial robots and factory automation.

- The government's strong support in the acquisition program has helped the country move towards Industry 4.0. For instance, Siasun, a China-based industrial robot maker, is affiliated with the Chinese Academy of Sciences, which is further linked to the government.

- With the rising cost of production in China and the strengthening of the Yuan against the Dollar, investors have been looking at alternate manufacturing destinations. However, manufacturers need to focus on quality production and environment-friendly manufacturing regulations. With the growing technology, a fully automated facility takes years to adjust and evolve. Meanwhile, unfavorable or delayed initiatives on active automation adaptation have limited growth on a regional basis.

China Factory Automation And Industrial Controls Market Trends

The Distributed Control System Segment is Expected to Hold a Significant Market Share

- DCS are process-oriented platforms that depend on interconnected sensors, controllers, terminals, and actuators to act as a centralized master controller for a facility's production operations. Thus, a DCS focuses on controlling and monitoring processes and allowing facility operators to see all facility operations from one place.

- One of the significant benefits of the DCS system is that the digital communication between distributed controllers, workstations, and other computing elements follows the peer-to-peer access principle. To achieve greater precision and control in process industries, like the petrochemical, nuclear, and oil and gas industries, there is an increasing demand for controllers that offer specified process tolerance around an identified set point.

- Moreover, many requirements have driven the adoption of DCS, as these systems provide lower operational complexity, project risk, and functionalities like flexibility for agile manufacturing in highly demanding applications. The ability of DCS to integrate PLCs, turbomachinery controls, safety systems, third-party controls, and various other plant process controls for heat exchangers, feedwater heaters, and water quality further drives the adoption of DCS in the energy sector.

- The growth in electric power generation in China is developing demand for distributed control systems (DCS). According to the national power industry statistics for the 2023 report published by CEC, the total installed electricity generation capacity in China in 2023 was 2919.6 gigawatts.

- In January 2022, China announced the use of dual control systems to control energy consumption. In the future, energy consumption and intensity will be transformed into a "dual control system" for carbon emissions and power. These initiatives will accelerate the adoption of the DCS system in the major manufacturing facilities between 2024 and 2029.

The Oil and Gas Sector is Expected to Register a Significant Growth

- The geographically dispersed oil and gas platforms require proper communication systems. Growth in solutions like PLC, SCADA, DCS, and safety automation is attributed to the enormous development of industries in China. It is also expected to create a massive demand for automation products that include DCS systems.

- In March 2023, Aramco signed definitive agreements to acquire a 10% shareholding in Shenzhen-listed Rongsheng Petrochemical Co. Ltd for CNY 24.6 billion (USD 3.6 billion); this would significantly expand its downstream presence in China. Under the strategic agreement, as part of an ongoing long-term sales arrangement with Rongsheng's subsidiary Zhejiang Petroleum and Chemical Co. Ltd, Aramco would supply this company with 480,000 barrels of Arabian crude oil daily.

- Moreover, the oil and gas industry is subject to several government regulations for safety, plant reliability, and efficiency. ICS finds applications in remote terminal units (RTU) and pumping and compression stations to ensure safety.

- The industry increasingly adopts ICS solutions to maintain safety and environmental integrity without compromising production efficiency. Automation helps integrate information and control, power, and safety solutions to meet the requirements of affordable energy and stringent government regulations.

- Moreover, owing to the high demand for automation in the oil and gas industry, Seeq expanded its support for the oil and gas industry by introducing new connectors to CygNet enterprise Supervisory Control and Data Acquisition (SCADA) Wellsite Information Transfer Markup Language (WITSML) data storage systems. This enables advanced analytics and faster data-based decision-making in the current challenging industry environment.

- Over the past few years, oil and gas companies have invested heavily in cybersecurity technologies, such as incident response solutions and software capable of collecting logs in ICS environments to enhance visibility and segmenting networks, prevent lateral movement, and eliminate imminent threats.

- The industry increasingly adopts ICS solutions to maintain safety and environmental integrity without compromising production efficiency. Automation helps integrate information and control, power, and safety solutions to meet the requirements of affordable energy and stringent government regulations.

China Factory Automation And Industrial Controls Industry Overview

The Chinese factory automation and industrial controls market is highly fragmented, with the presence of several prominent companies. Companies continuously invest in strategic partnerships and product developments to gain market share. Some of the recent developments in the market are:

- March 2024 - Rockwell Automation announced that it is collaborating with NVIDIA to accelerate the next-generation industrial architecture. To make it easier for automation customers to digitalize industrial processes, Rockwell plans to evolve the industry by building a future factory.

- February 2024 - ABB announced that it plans to leverage this integration of AI with robotics in sectors such as automotive, consumer goods, education, and emerging areas like healthcare, retail, and new energy. This strategic move aims to create additional value for customers by introducing new levels of autonomy in robotic applications across China.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Prominence of Automation Technologies Due to Declining Workforce

- 5.2 Market Challenges

- 5.2.1 Industry Policies and Regulations

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Control Systems

- 6.1.1.1 Distributed Control System (DCS)

- 6.1.1.2 PLC (Programmable Logic Controller)

- 6.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 6.1.1.4 Product Lifecycle Management (PLM)

- 6.1.1.5 Human Machine Interface (HMI)

- 6.1.1.6 Manufacturing Execution System (MES)

- 6.1.1.7 Enterprise Resource Planning (ERP)

- 6.1.1.8 Other Industrial Control Systems

- 6.1.2 Field Devices

- 6.1.2.1 Sensors and Transmitters

- 6.1.2.2 Electric Motors and Drives

- 6.1.2.3 Industrial Robotics

- 6.1.2.4 Machine Vision Systems

- 6.1.2.5 Other Field Devices

- 6.1.1 Industrial Control Systems

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power and Utilities

- 6.2.4 Automotive and Transportation

- 6.2.5 Pharmaceuticals

- 6.2.6 Food and Beverage

- 6.2.7 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 General Electric Company

- 7.1.2 Schneider Electric SE

- 7.1.3 Rockwell Automation Inc.

- 7.1.4 Honeywell International Inc.

- 7.1.5 Emerson Electric Company

- 7.1.6 ABB Ltd

- 7.1.7 Mitsubishi Electric Corporation

- 7.1.8 Siemens AG

- 7.1.9 Omron Corporation

- 7.1.10 Yokogawa Electric Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219