|

市场调查报告书

商品编码

1910587

印尼陶瓷砖市场:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Indonesia Ceramic Tiles - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

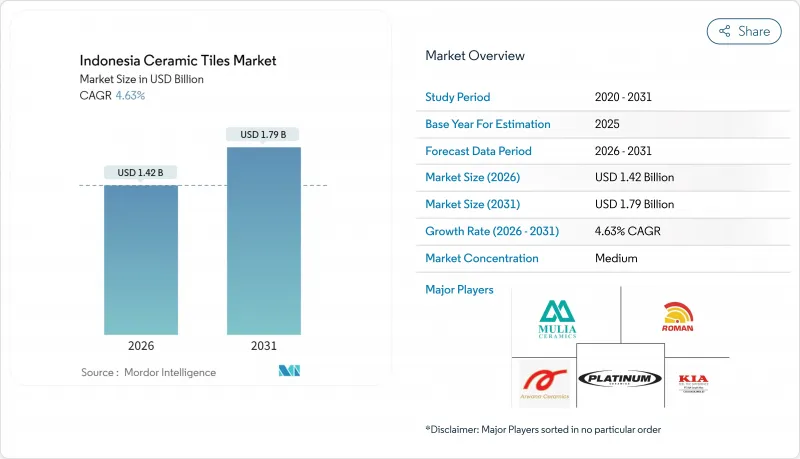

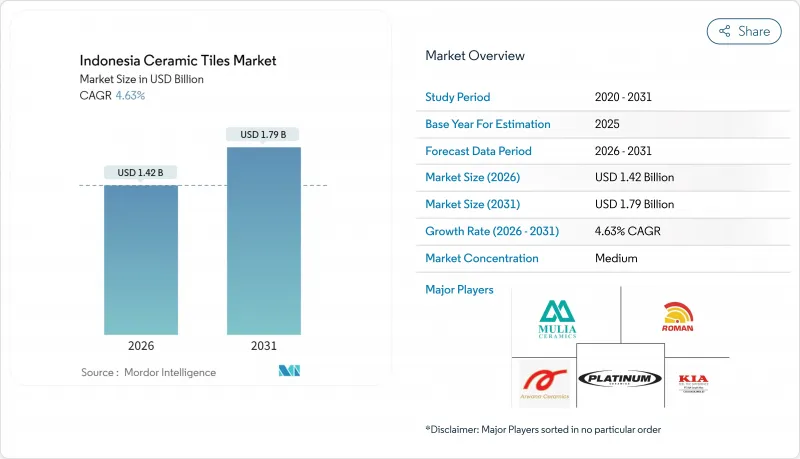

2025年印尼磁砖市场价值13.6亿美元,预计从2026年的14.2亿美元成长到2031年的17.9亿美元,在预测期(2026-2031年)内复合年增长率为4.63%。

需求成长势头源于政府的天然气补贴政策、对低成本进口商品征收100%至200%的关税壁垒,以及大规模的“300万套住宅建设计画”,这些因素共同推动了住宅、商业和公共计划的新订单。到2027年,印尼GDP预计将维持5.1%的强劲成长,持续的都市区进程,以及中等收入家庭不断增长的房屋维修支出,都为建设活动增添了多重韧性。製造商正利用瓷器耐用性的优势,而数位化销售管道的拓展也在一定程度上抵销了印尼高昂的岛际运输成本。此外,强制性的SNI品质标准也使本地生产商受益,该标准提高了进口商的准入门槛,并保护了高端市场的定价权。

印尼陶瓷砖市场趋势及洞察

能源密集陶瓷产业的天然气价格上限

根据特定天然气价格政策,每百万英热单位(MMBTU)6.75美元的价格上限已使瓷砖厂窑炉运作成本降低了约30%,为国内生产商带来了至关重要的成本优势。由于补贴将持续到2025年,工厂能够更好地保障原料供应并规划设备升级,进而增强了生产力计画的信心。受益主要集中在爪哇岛和苏门答腊岛,儘管全国供不应求,但这些地区的管线基础设施仍能支持运转率。补贴天然气有助于工厂缓解印尼币疲软对进口原料的影响。然而,天然气供应量仍仅为合约量的65-70%,燃料供应仍是近期产能扩张的阻碍因素。政府透过能源补贴支持国内製造业的综合策略与印尼的产业政策目标一致,将瓷砖产业定位为进口替代和出口扩张策略中的重要一环。

疫情后爪哇岛和峇里岛的住宅市场繁荣

由于优惠的房屋抵押贷款利率和税收激励措施,自出行限制放宽以来停滞的住宅计划已经復工,新房销售也随之活性化。爪哇岛60%的人口和58%的GDP集中在都市区,因此瓷砖需求主要集中在高密度公寓和独立式住宅。峇里岛的豪华别墅开发项目正在采用大尺寸、时尚的瓷砖,推高了平均售价。随着在家工作习惯的普及,住宅维修厨房和浴室,翻新需求也十分强劲。预计到2027年,这些因素将支撑超过一半的总需求成长。智慧家居技术和永续建筑实践在新住宅开发中的应用,为瓷砖製造商创造了机会,使其能够开发出满足不断变化的消费者需求和节能建筑监管要求的创新产品。

工业气体供应瓶颈

管网限制迫使许多窑炉以低于设计负载70%的负载运作,从而削弱了规模经济效益。频繁的压力下降扰乱了烧製週期,增加了废品率。分配过程中的寻租行为进一步加剧了生产计画的不确定性。不具备双燃料能力的製造商必须承担閒置成本或延后交货日期。投资者推迟产能扩张,直到电网升级能够确保稳定的电力供应。根据朝日新闻报道,外国投资者正在重新评估其在陶瓷行业的投资,这表明对供应可靠性的担忧导致资本形成和技术升级减少,而这些本可以支持市场扩张和提高竞争力。

细分市场分析

截至2025年,陶瓷瓷砖将占印尼陶瓷砖市场46.58%的份额,反映出瓷砖在购物中心、酒店和交通枢纽等场所的广泛应用,这些场所对瓷砖的耐磨性要求很高。雅加达和泗水商业房地产的快速扩张预计将推动印尼陶瓷瓷砖市场的成长。马赛克瓷砖虽然市场基数较小,但预计将以5.28%的复合年增长率增长,这主要得益于住宅在浴室和厨房整修中对个性化设计的偏好。当地企业正利用喷墨印刷和大型印刷技术来仿製大理石和木纹,从而抢占了原本用于天然石材的市场份额。此外,对低VOC釉药日益严格的监管也促使生产商采用更环保的配方,进一步提升了陶瓷瓷砖的高端形象。

更大的模组尺寸(60x120厘米、80x80厘米)的出现,推动了建筑师对高效施工和现代美学的需求。釉药防滑饰面在工业地板材料和户外露台中越来越受欢迎,在这些场所,功能安全性比视觉偏好更为重要。手工瓷砖在峇里岛的豪华度假村中占据一席之地,销量小规模但利润丰厚。能够将技术特性与时尚设计相结合的供应商继续主导着印尼瓷砖市场,尤其是那些拥有SNI认证的供应商,SNI认证让买家对产品的耐用性充满信心。节能快速的窑炉进一步降低了每平方公尺的成本,即使在燃料价格波动的情况下,也能保持价格竞争力。

到2025年,地板材料将占印尼瓷砖市场61.48%的份额,这主要得益于家庭对防水和易于清洁的优先考虑,尤其是在热带潮湿的气候条件下。开发商越来越多地采用3毫米的接缝和精细的边缘设计,以在高人流量的零售商店中创造无缝的视觉效果。屋顶瓦的复合年增长率将达到5.44%,以满足省会城市(这些城市易受恶劣天气影响)对耐热和抗飓风屋顶材料日益增长的需求。墙面装饰材料受益于医院和教育机构日益提高的卫生标准,这些场所对易于清洁的表面要求很高。印尼瓷砖行业也看到了模组化架空地板系统(整合通风和电缆)的成长潜力,该系统可用于建造面向未来的办公大楼。

抗菌釉药等持续的设计创新正在推动医院和食品加工厂对瓷砖的需求。瓷砖铺路石因其比木材更能承受高人流量和季风雨的侵蚀,正被广泛应用于户外露台。地暖系统曾经仅限于温带地区,如今也开始应用于印尼的豪华别墅,进一步提升了瓷砖的重要性。符合经合组织(OECD)耐腐蚀性标准的瓷砖屋顶已成为公共住宅维修中镀锌钢板的首选替代品。这种市场细分錶明,功能需求和不断发展的建筑标准支撑着瓷砖在各种应用领域的成长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 能源密集陶瓷产业的天然气价格上限

- 疫情后爪哇岛和峇里岛的住宅市场繁荣

- 提高对中国进口商品的关税

- 政府「百万住宅」计划

- 区域城市的快速都市化

- 中产阶级装潢支出增加

- 市场限制

- 工业气体供应瓶颈

- 印尼币疲软导致进口原料成本上升。

- 国内产能过剩加剧了价格竞争。

- 群岛间高的物流成本

- 产业价值链分析

- 波特五力分析

- 新进入者的威胁

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 洞察市场最新趋势与创新

- 深入了解近期产业发展动态(新产品发布、策略性倡议、投资、合作、合资、扩张、併购等)

第五章 市场规模及成长预测(金额单位:美元)

- 依产品类型

- 陶瓷瓷砖

- 釉药磁砖

- 无釉陶瓷砖

- 马赛克瓷砖

- 其他(装饰瓷砖、图案瓷砖、手工瓷砖)

- 透过使用

- 地板材料

- 墙

- 屋顶材料

- 最终用户

- 住宅

- 商业的

- 饭店业(饭店、度假村)

- 零售店

- 办公室和公共设施

- 卫生保健

- 教育设施

- 交通枢纽(机场、捷运、客运站)

- 其他商业用户

- 依建筑类型

- 新建工程

- 维修和更新

- 透过分销管道

- 磁砖和石材专卖店

- 居家装潢和DIY专卖店

- 线上零售

- 直接向建筑公司销售

- 按地区

- Java

- 苏门答腊

- 加里曼丹

- 苏拉威西

- 峇里岛和努沙登加拉

- 巴布亚及西巴布亚

- 马鲁古群岛

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Arwana Citramulia Tbk

- Mulia Keramik Indahraya

- Roman Ceramic International

- Platinum Ceramics Industry

- KIA Keramik Tbk

- Granito(PT Citra Granito)

- Diamond Keramik Indonesia

- Indogress(PT Inti Keramik Sejahtera)

- Indopenta Sakti Teguh

- Sun Power Ceramics

- Satyaraya Keramindo Indah(SRK)

- Candra Jaya Surya

- Royalboard Ceramics

- Sandimas Intimitra

- Terracotta Indonesia

- Muliakeramik Industri Indah

- Intikeramik Alamasri Industri Tbk

- Surya Toto Indonesia Tbk(Tile division)

- Dekkson Ceramics

- Madana Tiles Surabaya

第七章 市场机会与未来展望

The Indonesia ceramic tiles market was valued at USD 1.36 billion in 2025 and estimated to grow from USD 1.42 billion in 2026 to reach USD 1.79 billion by 2031, at a CAGR of 4.63% during the forecast period (2026-2031).

Demand momentum stems from the government's subsidized-gas policy, a 100-200% duty wall against low-cost imports, and the massive 3 Million Houses program, all of which drive fresh orders across residential, commercial, and public projects. Robust GDP growth of 5.1% through 2027, steady urban migration, and higher renovation spending among middle-income households add multiple layers of resilience to construction activity. Manufacturers capitalize on porcelain's durability-driven appeal, while digital sales channels widen geographic reach and partly offset Indonesia's high inter-island freight costs. Local producers also benefit from mandatory SNI quality standards that raise compliance hurdles for importers and protect pricing power in premium product niches.

Indonesia Ceramic Tiles Market Trends and Insights

Gas-price cap for energy-intensive ceramics

The USD 6.75 per MMBTU ceiling under the Certain Natural Gas Price Policy trims roughly 30% of kiln operating costs for tile plants, granting domestic producers a decisive cost edge. Capacity-planning confidence rises because the subsidy runs through 2025, enabling factories to lock in feedstock and schedule equipment upgrades. The benefit concentrates in Java and Sumatra, where pipeline infrastructure supports high utilization despite national supply gaps. Subsidized gas helps plants counter rupiah depreciation impacts on imported raw materials. However, deliveries cover only 65-70% of contracted volumes, turning fuel availability into a gating constraint for near-term output growth. The government's broader strategy of using energy subsidies to support domestic manufacturing aligns with Indonesia's industrial policy objectives, positioning ceramic tiles as a strategic sector for import substitution and export development initiatives.

Post-pandemic residential boom in Java & Bali

Mortgage rate incentives and tax relief revived stalled housing projects and spurred new launches once mobility restrictions eased. Java's urban centers account for 60% of population and 58% of GDP, funneling a large portion of tile demand into high-density apartment and landed-housing schemes. Bali's premium villa pipeline favors large-format, design-rich tiles that lift average selling prices. The renovation wave also stays strong as remote work habits push home-owners to upgrade kitchens and bathrooms. Collectively, these drivers underpin more than half of all volume additions through 2027. The integration of smart home technologies and sustainable building practices in new residential developments creates opportunities for ceramic tile manufacturers to develop innovative products that meet evolving consumer expectations and regulatory requirements for energy-efficient construction.

Industrial gas-supply bottlenecks

Pipeline network limits force many kilns to operate below 70% of design loads, eroding economies of scale. Frequent pressure drops interrupt firing cycles and raise reject rates. Rent-seeking behavior in allocation processes adds further uncertainty to production planning. Manufacturers without dual-fuel capability must absorb idle costs or delay deliveries. Investors defer capacity expansion until transmission upgrades assure steady volume. Foreign investors' reconsideration of ceramic industry investments, as reported by Asaki, demonstrates how supply reliability concerns translate into reduced capital formation and technological upgrading that could otherwise support market expansion and competitiveness improvements.

Other drivers and restraints analyzed in the detailed report include:

- Duty hike on Chinese imports

- Government "One Million Houses" program

- Depreciating rupiah inflates imported raw-material costs

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Porcelain tiles held a 46.58% share of the Indonesia ceramic tiles market in 2025, reflecting widespread acceptance in malls, hotels, and transit hubs where high abrasion resistance is crucial. The Indonesia ceramic tiles market size for porcelain is projected to widen alongside rapid commercial real-estate expansion in Jakarta and Surabaya. Mosaic formats, though starting at a smaller base, exhibit the highest 5.28% CAGR as homeowners embrace design individuality in bathroom and kitchen revamps. Domestic firms leverage ink-jet printing and large-slab presses to mimic marble and wood, capturing spend that once flowed to natural stone. Regulatory emphasis on low-VOC glazes also nudges producers toward eco-friendlier formulations, reinforcing porcelain's premium tag.

Value migration toward larger modules (60X120 cm and 80X80 cm) benefits efficient installation and modern aesthetics sought by architects. Unglazed and anti-slip variants gain traction in industrial floors and outdoor patios where functional safety tops visual preference. Handmade artisanal tiles retain a niche among luxury resorts in Bali, commanding high margins despite limited scale. The Indonesia ceramic tiles market continues to reward suppliers able to mesh technical attributes with on-trend looks, especially when backed by SNI certification that reassures buyers on durability benchmarks. Energy-efficient fast-firing kilns further lower cost per square meter, allowing competitive pricing even under fuel volatility.

Flooring captured 61.48% of the Indonesia ceramic tiles market share in 2025 because households value waterproofing and ease of cleaning amid tropical humidity. Developers increasingly specify 3-mm grout lines and rectified edges to achieve seamless visuals in high-traffic retail settings. Roofing tiles, expanding at 5.44% CAGR, meet rising demand for thermally stable, cyclone-resistant coverings in secondary cities prone to severe weather. Wall cladding benefits from heightening hygiene requirements in hospitals and educational premises where washable surfaces are mandatory. The Indonesia ceramic tiles industry also finds upside in modular raised-floor systems integrating airflow and cabling for future-ready office towers.

Continuous design innovation such as antibacterial glazes widens hospital and food-processing appeal. Outdoor decks adopt porcelain pavers that tolerate heavy footfall and monsoon deluges better than timber. Underfloor-heating compatibility, once limited to temperate markets, now appears in premium Indonesian villas, boosting ceramic relevance. Compliance with OECD resilience guidelines positions tile roofing as a preferred alternative to galvanized sheets in public housing upgrades. The segmentation underscores how functional imperatives and evolving building codes sustain diversified growth paths across applications.

The Indonesia Ceramic Tiles Market Report is Segmented by Product Type (Porcelain Tiles and More), Application (Floor, Wall, Roofing), End-User (Residential, Commercial), Construction Type (New Construction, Renovation and Replacement), Distribution Channel (Specialty Tile & Stone Stores, Home Improvement & DIY Stores, and More) and Geography (Java, Sumatra and More). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Arwana Citramulia Tbk

- Mulia Keramik Indahraya

- Roman Ceramic International

- Platinum Ceramics Industry

- KIA Keramik Tbk

- Granito (PT Citra Granito)

- Diamond Keramik Indonesia

- Indogress (PT Inti Keramik Sejahtera)

- Indopenta Sakti Teguh

- Sun Power Ceramics

- Satyaraya Keramindo Indah (SRK)

- Candra Jaya Surya

- Royalboard Ceramics

- Sandimas Intimitra

- Terracotta Indonesia

- Muliakeramik Industri Indah

- Intikeramik Alamasri Industri Tbk

- Surya Toto Indonesia Tbk (Tile division)

- Dekkson Ceramics

- Madana Tiles Surabaya

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Gas-price cap for energy-intensive ceramics

- 4.2.2 Post-pandemic residential boom in Java & Bali

- 4.2.3 Duty hike on Chinese imports

- 4.2.4 Government "One Million Houses" program

- 4.2.5 Rapid urbanisation of secondary cities

- 4.2.6 Rising middle-class renovation spending

- 4.3 Market Restraints

- 4.3.1 Industrial gas-supply bottlenecks

- 4.3.2 Depreciating rupiah inflates imported raw-material costs

- 4.3.3 Domestic over-capacity drives price wars

- 4.3.4 High inter-island logistics costs across the archipelago

- 4.4 Industry Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Suppliers

- 4.5.3 Bargaining Power of Buyers

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

- 4.6 Insights into the Latest Trends and Innovations in the Market

- 4.7 Insights on Recent Developments (New Product Launches, Strategic Initiatives, Investments, Partnerships, JVs, Expansion, M&As, etc.) in the Industry

5 Market Size & Growth Forecasts (Value in USD)

- 5.1 By Product Type

- 5.1.1 Porcelain Tiles

- 5.1.2 Glazed Ceramic Tiles

- 5.1.3 Unglazed Ceramic Tiles

- 5.1.4 Mosaic Tiles

- 5.1.5 Others (Decorative, Patterned, Handmade)

- 5.2 By Application

- 5.2.1 Floor

- 5.2.2 Wall

- 5.2.3 Roofing

- 5.3 By End-User

- 5.3.1 Residential

- 5.3.2 Commercial

- 5.3.2.1 Hospitality (Hotels, Resorts)

- 5.3.2.2 Retail Spaces

- 5.3.2.3 Offices & Institutions

- 5.3.2.4 Healthcare

- 5.3.2.5 Educational Facilities

- 5.3.2.6 Transport Hubs (Airports, Metro, Bus Terminals)

- 5.3.2.7 Other Commercial Users

- 5.4 By Construction Type

- 5.4.1 New Construction

- 5.4.2 Renovation and Replacement

- 5.5 By Distribution Channel

- 5.5.1 Specialty Tile & Stone Stores

- 5.5.2 Home Improvement & DIY Stores

- 5.5.3 Online Retail

- 5.5.4 Direct Sales to Contractors

- 5.6 By Geography

- 5.6.1 Java

- 5.6.2 Sumatra

- 5.6.3 Kalimantan

- 5.6.4 Sulawesi

- 5.6.5 Bali & Nusa Tenggara

- 5.6.6 Papua & West Papua

- 5.6.7 Maluku Islands

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Arwana Citramulia Tbk

- 6.4.2 Mulia Keramik Indahraya

- 6.4.3 Roman Ceramic International

- 6.4.4 Platinum Ceramics Industry

- 6.4.5 KIA Keramik Tbk

- 6.4.6 Granito (PT Citra Granito)

- 6.4.7 Diamond Keramik Indonesia

- 6.4.8 Indogress (PT Inti Keramik Sejahtera)

- 6.4.9 Indopenta Sakti Teguh

- 6.4.10 Sun Power Ceramics

- 6.4.11 Satyaraya Keramindo Indah (SRK)

- 6.4.12 Candra Jaya Surya

- 6.4.13 Royalboard Ceramics

- 6.4.14 Sandimas Intimitra

- 6.4.15 Terracotta Indonesia

- 6.4.16 Muliakeramik Industri Indah

- 6.4.17 Intikeramik Alamasri Industri Tbk

- 6.4.18 Surya Toto Indonesia Tbk (Tile division)

- 6.4.19 Dekkson Ceramics

- 6.4.20 Madana Tiles Surabaya

7 Market Opportunities & Future Outlook

- 7.1 Rapid-set thin-tile technology for high-rise retrofits

- 7.2 "Smart-surface" IoT-embedded floor tiles