|

市场调查报告书

商品编码

1911342

日本润滑油市场-份额分析、产业趋势与统计、成长预测(2026-2031)Japan Lubricants - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

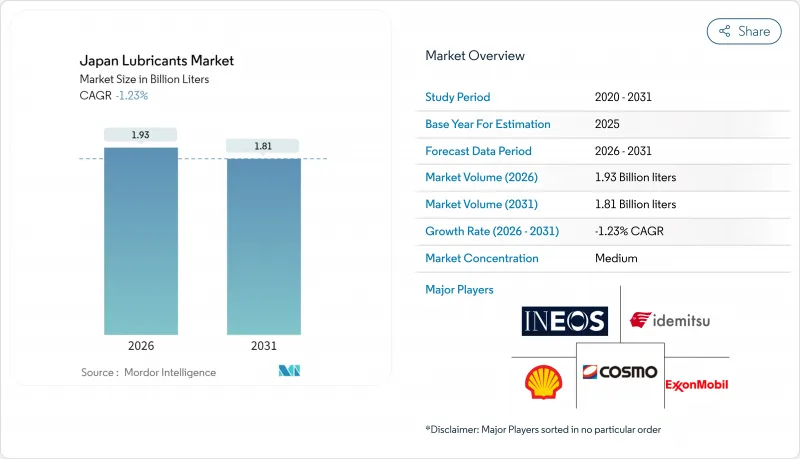

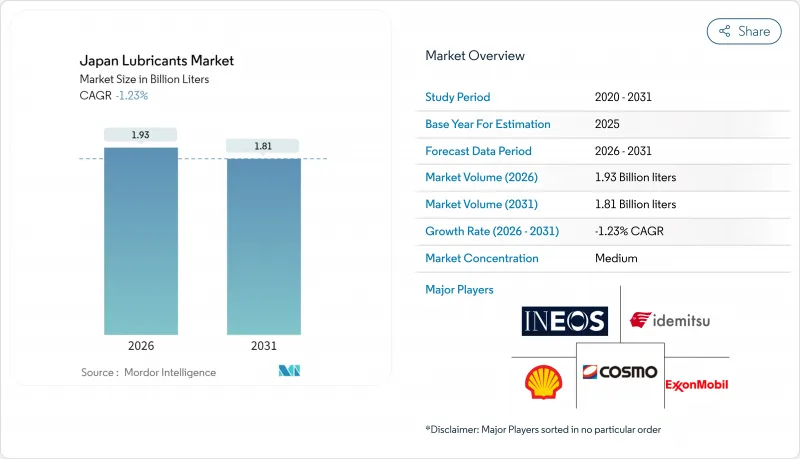

预计到2026年,日本润滑油市场规模将达到19.3亿公升,低于2025年的19.5亿公升。到2031年,预计市场规模将达到18.1亿升,2026年至2031年的复合年增长率为-1.23%。

这种负成长反映了汽车生产结构性变化、电动动力传动系统总成普及以及换油週期延长等因素的综合影响,所有这些因素都在抑製成熟经济体的总需求。然而,由于混合动力汽车仍需要自动变速箱油(ATF)、电驱动桥润滑油和温度控管油,需求依然强劲;同时,工业自动化、资料中心冷却和永续性措施也创造了成长机会。这稳定了综合炼油企业的利润率。日本主要企业——ENEOS、出光兴产和科斯莫能源——在需求下降的情况下,透过利用其炼油能力、广泛的销售网络以及与原始设备製造商(OEM)的技术合作,保持了价格纪律。新的法规要求到2035年废油回收量达到17.5千万公升,到2040年达到35万千升,这使得再生基础油成为一个具有战略竞争力的领域。现有企业正在投资建置闭合迴路供应链,以符合经济产业省所订定的循环经济目标。

日本润滑油市场趋势与分析

电动车和混合动力汽车润滑油市场成长

丰田的「混合动力优先」策略(预计到2024年,混合动力汽车将占日本国内销量的40%)正在降低对传统机油的需求,但维持着对自动变速箱油、电驱动桥润滑脂和逆变器冷却油的需求。由于混合动力传动系统结合了电动马达和内燃机,每个单元仍然需要小油底壳发动机油,以及专为高扭矩、低粘度运行而设计的专用传动系统油液。能够配製添加铜腐蚀抑制剂的低黏度自动变速箱油的供应商正在赢得市场份额,以延长紧凑型变速驱动桥内部件的使用寿命。丰田公开宣布的多路径电气化蓝图还包括探索燃料电池和合成燃料,这将进一步延缓向纯电动车的快速过渡。这使得日本润滑油市场能够提供差异化的化学产品,而不是传统的单一黏度润滑油。

资料中心采用浸没式冷却液

位于东京和大阪的超大规模资料中心营运商正从传统的风冷机架转向单相浸没式冷却槽,以应对人工智慧工作负载带来的日益增长的热负荷。 ENEOS 和 Idemitsu Kosan 提供的介电液能够将热量直接传递到晶片,使每个机架的功率密度超过 75kW,同时避免效能限制。这些专用介电液具有抗氧化性、超低挥发性和不导电性,使营运商能够省去冷却设备、降低风扇能耗并延长伺服器寿命。虽然绝对销量仍然较低,但单价超过每公升 12 美元,使其成为日本润滑油市场中附加价值最高的领域。

内燃机汽车产量下降

日本汽车製造商持续将组装和动力传动系统生产转移到成本更具竞争力的海外工厂,导致日本国内内燃机产量下降。因此,日本国内工厂的引擎油和消费量油灌装量也正在减少。电动车进一步加剧了这一下降趋势,因为与传统内燃机车型相比,电动车的润滑油消耗量可减少70%。这种萎缩趋势迫使润滑油调配商调整其本地产能,转向生产更高价值的电动车动力总成润滑油,并进行大量生产以出口。

细分市场分析

截至2025年,汽车机油占日本润滑油市场的33.33%。然而,由于混合动力汽车和电池式电动车的日益普及,导致承油盘容量减小、换油週期延长,这一细分市场正在稳步萎缩。高里程混合动力汽车仍然需要0W-8和0W-12黏度的机油来降低摩擦,因此,专注于超低黏度合成机油的配方商仍然具有重要意义。工业机油将以0.02%的适度复合年增长率增长,但由于对备用柴油发电机的需求,以支持资料中心的可靠性和飓风应急发电,其销量在宏观经济环境平稳的情况下仍在增长。

变速箱油市场呈现两极化趋势。由于内燃机(ICE)产量下降,传统自动变速箱油(ATF)的需求正在减少,而混合动力变速驱动桥和电驱动桥冷却液的需求却在增长,供应商正加大促销对铜友好的抗氧化剂配方。齿轮油,尤其是ISO 320和ISO 460等级的齿轮油,受益于机器人和精密机械设备的普及,这些设备需要更长的使用寿命和抗微点蚀的化学成分。受施工机械更换需求以及资料中心升降系统采用阻燃磷酸酯的推动,液压油的需求预计将在一定程度上缓解整体市场的下滑。润滑脂市场依然强劲,这得益于风力发电机变桨轴承和电动方向盘装置的需求。虽然加工油油和金属加工油的销售量保持平稳,但由于更严格的环保标准,合成油和水溶性油的需求不断增长,单价也随之上涨。涡轮机油和变压器油的需求与日本可再生能源扩张计划和电网现代化计划相关的维护週期密切相关。

日本润滑油市场报告按产品类型(汽车引擎油、工业引擎油、变速箱油、齿轮油、煞车油、液压油、润滑脂等)、终端用户产业(汽车、船舶、航太、重型机械、工业)、基础油类型(矿物油、合成油、半合成油、生物基油)和地区(日本)对市场进行分析。市场预测以公升为单位。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电动车和混合动力汽车润滑油市场成长

- 工业自动化程度的提高推动了对油压油和齿轮油的需求。

- 老旧车队持续推高车辆更新需求

- 资料中心浸没式冷却剂的应用

- 企业净零排放目标推动生物基润滑油的发展

- 促进石油回收的循环经济政策

- 市场限制

- 内燃机汽车产量下降

- 成熟的工业生产限制了产量扩张。

- 原厂延长换油週期可降低每辆车的消费量。

- 低成本进口再生油

- 价值链分析

- 法律规范

- 终端用户趋势

- 汽车产业

- 製造业

- 发电业

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 依产品类型

- 汽车引擎油

- 工业机油

- 变速箱油

- 齿轮油

- 煞车油

- 油压

- 润滑脂

- 加工油(包括橡胶加工油和白油)

- 金属加工油

- 涡轮机油

- 变压器油

- 其他产品类型

- 按最终用户行业划分

- 车

- 搭乘用车

- 商用车辆

- 摩托车

- 船

- 航太

- 重型机械

- 建造

- 矿业

- 农业

- 工业的

- 发电

- 冶金/金属加工

- 纺织业

- 石油和天然气

- 其他终端用户产业

- 车

- 依基础油类型

- 矿物油性润滑剂

- 合成润滑油

- 半合成润滑油

- 生物性润滑剂

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率**(%)/排名分析

- 公司简介

- ENEOS Corporation

- Idemitsu Kosan Co., Ltd.

- Cosmo Energy Holdings Co., Ltd.

- ExxonMobil Corporation

- BP Plc(Castrol)

- KYODO YUSHI CO., LTD.

- FUCHS SE

- Japan Sun Oil Co. Ltd.(SUNOCO Inc.)

- Mitasu Oil Corporation

- Yushiro Chemical Industry Co., Ltd.

- TotalEnergies SE

- Shell plc

- KYODO YUSHI CO., LTD.

第七章 市场机会与未来展望

第八章:执行长面临的关键策略挑战

Japan lubricants market size in 2026 is estimated at 1.93 billion liters, growing from 2025 value of 1.95 billion liters with 2031 projections showing 1.81 billion liters, growing at -1.23% CAGR over 2026-2031.

The negative trajectory reflects structural changes in vehicle production, the advancement of electrified powertrains, and longer drain intervals, which collectively curb overall volumes in this mature economy. Demand nonetheless remains meaningful because hybrid vehicles still require automatic-transmission fluids, e-axle lubricants, and thermal-management oils, while industrial automation, data-center cooling, and sustainability mandates create pockets of growth that stabilize margins for integrated refiners. Domestic leaders ENEOS, Idemitsu, and Cosmo Energy rely on their refining footprints, extensive distributor networks, and technical relationships with original equipment manufacturers to preserve pricing discipline even as volumes slide. New regulations targeting 175,000 kL of waste-oil recycling by 2035 and 350,000 kL by 2040 have turned re-refined base stocks into a strategic battleground, with incumbents investing in closed-loop supply chains to align with circular economy objectives set by Japan's Ministry of Economy, Trade, and Industry.

Japan Lubricants Market Trends and Insights

Growth in EV and hybrid-specific lubricants

Toyota's hybrid-first strategy, exemplified by hybrids accounting for 40% of the OEM's 2024 domestic sales, preserves demand for automatic-transmission fluids, e-axle greases, and inverter-cooling oils even as conventional engine-oil volumes erode. Hybrid powertrains combine electric motors with internal-combustion engines, meaning each unit still needs small-sump engine oils plus specialized driveline fluids tuned for high-torque, low-viscosity operation. Suppliers able to formulate low-viscosity automatic-transmission fluids with copper-corrosion inhibitors gain share because they extend component life in compact transaxles. Toyota's well-publicized multi-pathway electrification roadmap, which keeps fuel-cell and synthetic-fuel research in scope, further delays an abrupt battery-electric pivot, allowing the Japan lubricants market to sell differentiated chemistries instead of conventional mono-grade oils.

Data-center immersion-cooling fluids adoption

Hyperscale operators based in Tokyo and Osaka are replacing legacy air-cooling racks with single-phase immersion tubs to accommodate rising thermal loads from artificial-intelligence workloads. Dielectric fluids supplied by ENEOS and Idemitsu enable direct-to-chip heat transfer, allowing power densities above 75 kW per rack without performance throttling. These niche fluids deliver oxidation stability, ultra-low volatility, and non-conductivity, letting operators eliminate chillers, reduce fan energy, and raise server life expectancy. Although absolute volumes remain small, unit prices exceed USD 12 per liter, positioning the segment as the highest value pool within the Japanese lubricants market.

Declining ICE vehicle production

Domestic automakers continue to shift final assembly and powertrain production to cost-competitive overseas plants, removing internal-combustion engine output from Japan and thus shrinking in-country fill volumes for factory-fill engine and gear oils. Electric vehicles require as much as 70% fewer lubricants by volume compared with typical ICE models, deepening the consumption slide. The contraction forces lubricant blenders to rationalize local capacity and pivot to higher-value electric-driveline fluids or export-oriented batches.

Other drivers and restraints analyzed in the detailed report include:

- Industrial automation is boosting hydraulic and gear oils

- Corporate net-zero targets driving bio-based lubricants

- Mature industrial output limiting volume expansion

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Automotive engine oils held a 33.33% share of the Japanese lubricants market in 2025, but the segment is contracting steadily as hybrids and battery electric vehicles reduce sump sizes and extend oil-change intervals. High-mileage hybrid vehicles still depend on 0W-8 and 0W-12 viscosities to minimize friction, so formulators geared toward ultralow-viscosity synthetics maintain relevance. Industrial engine oils, although growing at a modest 0.02% CAGR, benefit from backup diesel generators that support data center resiliency and hurricane emergency power protocols, adding incremental liters in a flat macroeconomic environment.

Transmission fluids face a bifurcation: demand for conventional automatic-transmission fluids declines in tandem with ICE output, whereas hybrid-transaxle and e-axle coolants expand, prompting suppliers to market copper-friendly, antioxidation packages. Gear oils, especially ISO 320 and ISO 460 grades, benefit from robotics and precision-machinery installations that require long-life, anti-micropitting chemistry. Hydraulic-fluid demand aligns with the renewal of construction equipment and the adoption of fire-resistant phosphate esters in data-center lift systems, slightly moderating the total market decline. Greases remain resilient, powered by wind-turbine pitch bearings and electrified power-steering units. Process oil and metalworking fluid volumes plateau, but synthetics and water-soluble versions command a higher unit value under tighter environmental standards. Turbine and transformer oil turnover follows maintenance cycles within Japan's renewable-energy build-out and grid modernization programs.

The Japan Lubricants Market Report is Segmented by Product Type (Automotive Engine Oil, Industrial Engine Oil, Transmission Fluids, Gear Oil, Brake Fluids, Hydraulic Fluids, Greases, and More), End-User Industry (Automotive, Marine, Aerospace, Heavy Equipment, Industrial), Base Stock Type (Mineral Oil-Based, Synthetic, Semi-Synthetic, Bio-Based), and Geography (Japan). The Market Forecasts are Provided in Terms of Volume (Liters).

List of Companies Covered in this Report:

- ENEOS Corporation

- Idemitsu Kosan Co., Ltd.

- Cosmo Energy Holdings Co., Ltd.

- ExxonMobil Corporation

- BP Plc (Castrol)

- KYODO YUSHI CO., LTD.

- FUCHS SE

- Japan Sun Oil Co. Ltd. (SUNOCO Inc.)

- Mitasu Oil Corporation

- Yushiro Chemical Industry Co., Ltd.

- TotalEnergies SE

- Shell plc

- KYODO YUSHI CO., LTD.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in EV / Hybrid-specific lubricants

- 4.2.2 Rising industrial automation boosting hydraulic and gear lubes

- 4.2.3 Aging vehicle fleet sustaining replacement demand

- 4.2.4 Data-center immersion-cooling fluids adoption

- 4.2.5 Corporate net-zero targets driving bio-based lubricants

- 4.2.6 Circular-economy policies promoting re-refined oils

- 4.3 Market Restraints

- 4.3.1 Declining ICE vehicle production

- 4.3.2 Mature industrial output limiting volume expansion

- 4.3.3 OEM long-drain intervals reduce consumption per vehicle

- 4.3.4 Low-cost imports of re-refined oils

- 4.4 Value Chain Analysis

- 4.5 Regulatory Framework

- 4.6 End-User Trends

- 4.6.1 Automotive Industry

- 4.6.2 Manufacturing Industry

- 4.6.3 Power Generation Industry

- 4.7 Porter's Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Product Type

- 5.1.1 Automotive Engine Oil

- 5.1.2 Industrial Engine Oil

- 5.1.3 Transmission Fluids

- 5.1.4 Gear Oil

- 5.1.5 Brake Fluids

- 5.1.6 Hydraulic Fluids

- 5.1.7 Greases

- 5.1.8 Process Oil (Including Rubber Process Oil and White Oil)

- 5.1.9 Metalworking Fluids

- 5.1.10 Turbine Oil

- 5.1.11 Transformer Oil

- 5.1.12 Other Product Types

- 5.2 By End-user Industry

- 5.2.1 Automotive

- 5.2.1.1 Passenger Vehicles

- 5.2.1.2 Commercial Vehicles

- 5.2.1.3 Two-Wheelers

- 5.2.2 Marine

- 5.2.3 Aerospace

- 5.2.4 Heavy Equipment

- 5.2.4.1 Construction

- 5.2.4.2 Mining

- 5.2.4.3 Agriculture

- 5.2.5 Industrial

- 5.2.5.1 Power Generation

- 5.2.5.2 Metallurgy and Metalworking

- 5.2.5.3 Textiles

- 5.2.5.4 Oil and Gas

- 5.2.5.5 Other End-Use Industries

- 5.2.1 Automotive

- 5.3 By Base Stock Type

- 5.3.1 Mineral Oil-Based Lubricants

- 5.3.2 Synthetic Lubricants

- 5.3.3 Semi-Synthetic Lubricants

- 5.3.4 Bio-Based Lubricants

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share**(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ENEOS Corporation

- 6.4.2 Idemitsu Kosan Co., Ltd.

- 6.4.3 Cosmo Energy Holdings Co., Ltd.

- 6.4.4 ExxonMobil Corporation

- 6.4.5 BP Plc (Castrol)

- 6.4.6 KYODO YUSHI CO., LTD.

- 6.4.7 FUCHS SE

- 6.4.8 Japan Sun Oil Co. Ltd. (SUNOCO Inc.)

- 6.4.9 Mitasu Oil Corporation

- 6.4.10 Yushiro Chemical Industry Co., Ltd.

- 6.4.11 TotalEnergies SE

- 6.4.12 Shell plc

- 6.4.13 KYODO YUSHI CO., LTD.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment