|

市场调查报告书

商品编码

1636459

印度电动汽车电池製造设备:市场占有率分析、产业趋势/统计、成长预测(2025-2030)India Electric Vehicle Battery Manufacturing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

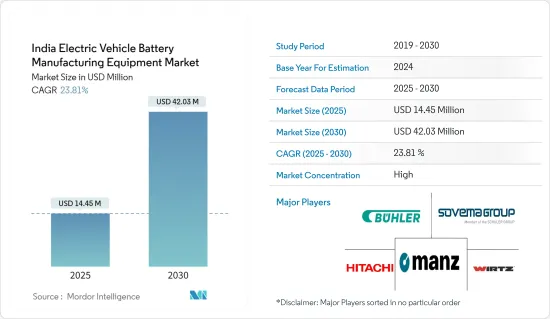

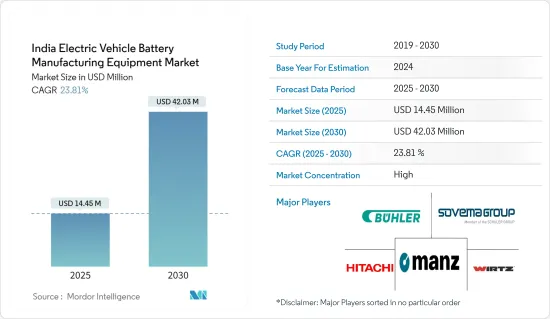

印度电动车电池製造设备市场规模预计到2025年为1,445万美元,预计2030年将达到4,203万美元,预测期内(2025-2030年)复合年增长率为23.81%。

主要亮点

- 从中期来看,政府对电池製造的政策和投资的增加以及电池原材料成本的降低预计将在预测期内推动对电动车电池製造设备的需求。

- 另一方面,新兴经济体缺乏技术诀窍可能会严重限制电动车电池製造设备市场的成长。

- 然而,电动车的长期目标,如扩大产能、增强技术进步和降低成本,预计将在不久的将来为电动车电池製造设备市场的参与者创造重大机会。

印度电动车电池製造设备市场趋势

电池原物料成本下降正在推动市场

- 由于原物料成本下降,印度电动车(EV)电池製造业正在经历转型。锂、钴、镍、石墨等主要原物料价格下跌。价格下降不仅降低了整体生产成本,还使电动车电池变得更便宜,并推动了电动车市场的成长。

- 锂离子 (Li-ion) 电池处于电动车 (EV) 市场革命的前沿,并刺激了电池製造的创新。近年来,全球锂离子电池价格大幅下跌,且这一趋势预计将持续下去。价格下降对于让更多消费者负担得起电动车发挥关键作用。

- 例如,彭博新能源财经强调 2023 年锂离子电池价格将大幅下降。价格跌至 139 美元/kWh,下降 13%。这种下降趋势预计将持续下去,到 2025 年降至 113 美元/千瓦时,到 2030 年降至 80 美元/千瓦时。

- 此外,印度正在共同努力确保锂、钴和镍等关键材料的稳定和道德的供应。然而,这种追求充满挑战。为了应对原材料挑战,印度正在探索国内蕴藏量并建立国际合作。该国的重点是利用其矿产资源来满足对电动车电池材料不断增长的需求。

- 例如,2023年2月,印度地质调查局(GSI)在查谟和克什米尔Reshi地区的Salal-Haimana地区发现锂蕴藏量估计为590万吨。锂是非铁金属,对于电池能源储存系统和电动车 (EV) 电池至关重要。这项发现满足了电动车对锂不断增长的需求,并增加了对电动车电池製造设备的需求。

- 此外,替代材料和电池化学物质的探索正在减少对昂贵原料的依赖。这种转变不仅会降低成本,还会提高电池生产的永续性和效率。公司也投资研发,以发现可进一步提高电池性能和寿命的新材料。

- 例如,2023年11月,电动车电池领域知名企业SK On Co., Ltd.与电池材料领先製造商BASFSE公司合作。两家公司的共同使命是开发用于锂离子电池的先进材料,目标市场是北美和亚太地区,特别是印度。此次合作不仅增强了两家公司的市场地位,而且正值绿色汽车产业放缓之际。这些进步可能会在短期内压低电池价格并增加对电动车电池製造设备的需求。

- 此类计划和创新可能会降低全部区域的原材料成本,并在预测期内增加对电动车电池製造设备的需求。

锂离子电池占市场主导地位

- 在印度,锂离子电池的兴起正在显着改变电动车(EV)电池製造设备产业。随着电动车对锂离子电池的需求增加,对专业製造设备的需求也增加。这包括製造电极、组装电池、执行成型和老化过程以及组装电池组的机器。印度电动车销售的大幅成长和电池需求的并行激增凸显了对先进製造设备的迫切需求,以确保高效和可扩展的生产。

- 例如,根据国际能源总署(IEA)的报告,2023年印度电动车销量将达到8.2万辆,比2022年增长惊人的70.8%,比2019年增长119倍。据预测,电动车销量将继续大幅成长,进一步增加该地区电池製造设备的需求。

- 此外,在当地投资和与全球技术提供者伙伴关係的推动下,我们共同努力建立最先进的製造设施。此举将推动创新、提高产能并满足对先进能源储存解决方案不断增长的需求。

- 例如,2024年7月,Ola Electric宣布计画投资1亿美元在泰米尔纳德邦兴建超级工厂,生产本土锂离子电池。该公司计划在明年初之前从韩国和中国进口电池转向自己生产电池。此举预计将提高国内电池产量,进而增加对製造设备的需求。

- 为了促进国内电动车电池产量,印度政府推出了一系列政策和奖励。这包括对製造设备的补贴、税收优惠以及对电池技术研发的支援。

- 例如,政府制定了雄心勃勃的2023年电动车销售目标,并计划在2030年实现30%的私家车、70%的商用车、80%的两轮车和三轮车的电动化。此外,还推出了每千瓦时 10,000 印度卢比(120 美元)至 15,000 印度卢比(180 美元)的补贴奖励措施。这些努力不仅将促进电动车的生产和销售,还将在未来几年显着增加对电池製造设备的需求。

- 总之,在政府的支持和产业动力的推动下,印度对电动车电池製造设备的需求预计在可预见的未来将大幅增加。

印度电动汽车电池製造设备产业概况

印度的电动车电池製造设备整合度中等。主要参与者(排名不分先后)包括 Manz AG、Wirtz Manufacturing、Buhler AG、Sovema Group SpA 和 Hitachi。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规政策

- 市场动态

- 促进因素

- 电池製造的政府政策和投资

- 电池原物料成本下降

- 抑制因素

- 新兴经济体缺乏技术诀窍

- 促进因素

- 供应链分析

- PESTLE分析

- 投资分析

第五章市场区隔

- 按流程

- 混合物

- 涂层

- 日历

- 狭缝/电极加工

- 其他工艺

- 透过电池

- 锂离子

- 铅酸电池

- 镍氢电池

- 其他电池

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- Manz AG

- Hitachi Ltd.

- Wirtz Manufacturing India Pvt. Ltd.

- Buhler AG

- Sovema Group SpA

- Tata Chemicals

- Luminous Power Technologies

- kaya Power Group

- ACME Cleantech Solutions

- Inobat

- 其他知名企业名单

- 市场排名分析

第七章 市场机会及未来趋势

- 电动车的长期目标

简介目录

Product Code: 50003726

The India Electric Vehicle Battery Manufacturing Equipment Market size is estimated at USD 14.45 million in 2025, and is expected to reach USD 42.03 million by 2030, at a CAGR of 23.81% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, rising government policies and investments towards battery manufacturing and a decline in the cost of battery raw materials are expected to drive the demand for electric vehicle battery manufacturing equipment during the forecast period.

- On the other hand, the shortage of technological know-how in developing economies can significantly restrain the growth of the electric vehicle battery manufacturing equipment market.

- Nevertheless, the long-term ambitious targets for electric vehicles like scaling up production capacity, enhancing technological advancements, and reducing costs are expected to create significant opportunities for electric vehicle battery manufacturing equipment market players in the near future.

India Electric Vehicle Battery Manufacturing Equipment Market Trends

Decline in the Cost of Battery Raw Materials Drives the Market

- India's electric vehicle (EV) battery manufacturing industry is undergoing a transformation, driven by falling raw material costs. Key materials such as lithium, cobalt, nickel, and graphite have seen price reductions. This decline is not only lowering overall production costs but also making EV batteries more affordable, thus fueling the growth of the EV market.

- Lithium-ion (Li-ion) batteries have been at the forefront of the electric vehicle (EV) market revolution, spurring innovations in battery production. In recent years, global prices for lithium-ion batteries have dropped significantly, a trend that's set to continue. This price dip has played a crucial role in enhancing the affordability and accessibility of electric vehicles for a wider consumer base.

- For instance, Bloomberg NEF highlighted that, lithium-ion battery prices in 2023 marked a notable decline. Prices fell to USD 139/kWh, reflecting a 13% drop. Looking ahead, projections indicate this downward trend will continue, with prices expected to hit USD 113/kWh by 2025 and dive to USD 80/kWh by 2030, driven by relentless technological and manufacturing advancements.

- Moreover, India is making concerted efforts to ensure a stable and ethical supply of vital materials like lithium, cobalt, and nickel. However, this pursuit is fraught with challenges. To address the raw material conundrum, India is exploring its domestic reserves and establishing international collaborations. The country's focus is on harnessing its mineral wealth to meet the burgeoning demand for EV battery materials.

- For instance, in February 2023, the Geological Survey of India (GSI) discovered lithium reserves estimated at 5.9 million tonnes in the Salal-Haimana region of Jammu and Kashmir's Reasi district. Lithium, a non-ferrous metal, is crucial for battery energy storage systems and electric vehicle (EV) batteries. This find is set to cater to the rising lithium demand for EVs, subsequently amplifying the need for equipment in electric vehicle battery manufacturing.

- Additionally, the exploration of alternative materials and battery chemistries is diminishing the dependence on costly raw materials. This shift not only curtails expenses but also enhances the sustainability and efficiency of battery production. Companies are also investing in research and development to discover new materials that can further boost battery performance and longevity.

- For instance, in November 2023, SK On Co., a prominent player in the electric vehicle battery arena, teamed up with BASF SE, a leading battery materials producer. Their joint mission is to pioneer advanced materials for lithium-ion batteries, targeting markets in North America and the Asia-Pacific, with a keen focus on India. This partnership not only strengthens their market position but also comes at a time when the green automobile sector is witnessing a slowdown. Such advancements are poised to drive down battery prices and elevate the demand for EV battery manufacturing equipment in the foreseeable future.

- Such type of projects and inovations are likely to decline the cost of raw materials across the region and rising demand of EV battery manufacturing equipment during the forecast period.

Lithium-Ion Battery Type Dominate the Market

- In India, the rise of lithium-ion batteries has significantly shaped the electric vehicle (EV) battery manufacturing equipment industry. As the demand for lithium-ion batteries in EVs grows, so does the need for specialized manufacturing equipment. This includes machinery for producing electrodes, assembling cells, conducting formation and aging processes, and putting together battery packs. With a notable increase in EV sales in India, the parallel surge in battery demand highlights the urgent need for advanced manufacturing equipment to ensure efficient and scalable production.

- For instance, in 2023, the International Energy Agency (IEA) reported electric vehicle sales in India reached 82,000 units, marking a 70.8% increase from 2022 and an astonishing 119-fold jump from 2019. Projections indicate a continued surge in EV sales, further driving the demand for battery manufacturing equipment in the region.

- Moreover, there's a concerted effort to establish cutting-edge manufacturing facilities, backed by both local investments and partnerships with global technology providers. The focus is on producing high-quality lithium-ion batteries, a move set to drive innovation, enhance production capacity, and meet the growing appetite for advanced energy storage solutions.

- For instance, in July 2024, Ola Electric unveiled plans to invest USD 100 million in its Tamil Nadu gigafactory, aiming to produce indigenous lithium-ion batteries. The company intends to transition to its battery cells by early next year, moving away from current imports from Korea and China. Such strides are anticipated to boost the country's battery production and, in turn, elevate the demand for manufacturing equipment.

- In a bid to strengthen domestic EV battery production, the Indian government has introduced a suite of policies and incentives. These include subsidies for manufacturing equipment, tax incentives, and support for battery technology research and development.

- For instance, in 2023, the government set ambitious EV sales targets: by 2030, they aim for 30% of private cars, 70% of commercial vehicles, and a remarkable 80% of two and three-wheelers to be electric. Additionally, subsidy incentives have been introduced, ranging from INR 10,000 per kWh (USD 120) to INR 15,000 per kWh (USD 180). These initiatives are poised to not only boost EV production and sales but also significantly heighten the demand for battery manufacturing equipment in the coming years.

- In conclusion, with the government's backing and the industry's momentum, the demand for EV battery manufacturing equipment in India is set to witness a substantial rise in the foreseeable future.

India Electric Vehicle Battery Manufacturing Equipment Industry Overview

India's electric vehicle battery manufacturing equipment is moderately consolidated. Some key players (not in particular order) are Manz AG, Wirtz Manufacturing, Buhler AG, Sovema Group S.p.A, Hitachi Ltd., among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Government Policies and Investments towards battery manufacturing

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Dearth of technological know-how in developing economies

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE ANALYSIS

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Process

- 5.1.1 Mixing

- 5.1.2 Coating

- 5.1.3 Calendering

- 5.1.4 Slitting and Electrode Making

- 5.1.5 Other Process

- 5.2 Battery

- 5.2.1 Lithium-ion

- 5.2.2 Lead-Acid

- 5.2.3 Nickel Metal Hydride Battery

- 5.2.4 Other Batteries

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Manz AG

- 6.3.2 Hitachi Ltd.

- 6.3.3 Wirtz Manufacturing India Pvt. Ltd.

- 6.3.4 Buhler AG

- 6.3.5 Sovema Group S.p.A

- 6.3.6 Tata Chemicals

- 6.3.7 Luminous Power Technologies

- 6.3.8 kaya Power Group

- 6.3.9 ACME Cleantech Solutions

- 6.3.10 Inobat

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Long-term ambitious targets for electric vehicles

02-2729-4219

+886-2-2729-4219