|

市场调查报告书

商品编码

1687187

美国工程塑胶:市场占有率分析、产业趋势和成长预测(2024-2029)United States Engineering Plastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

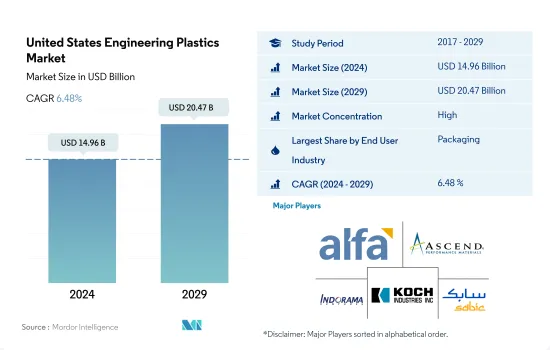

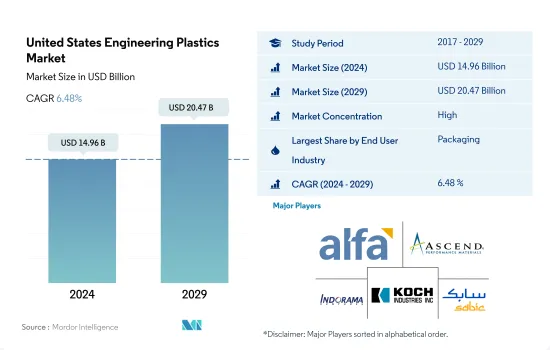

预计 2024 年美国工程塑胶市场规模为 149.6 亿美元,到 2029 年将达到 204.7 亿美元,预测期内(2024-2029 年)的复合年增长率为 6.48%。

先进材料的应用日益广泛,推动工程塑胶需求

- 工程塑胶的应用范围包括航太领域的内墙板和门以及硬质和软质包装。工程塑胶因其重量轻、强度高、低疲劳和低可燃性等优良特性而受到许多行业的欢迎。美国工程塑胶市场受到包装、电气和电子以及汽车等行业的推动。

- 在美国,包装产业贡献了最大的市场收益占有率,预计在预测期内将成长5.93%。塑胶包装的需求主要来自食品和饮料行业。此外,对已调理食品、网路食品购买等的需求不断增长,也推动了该国包装产业的发展。 2022年美国塑胶包装产量为17.8万吨。与2021年相比,2022年包装产业对工程塑胶的需求以金额为准成长率为7.71%。

- 美国电气和电子产业是工程塑胶的第二大市场,预计在预测期内(2023-2029年)以金额为准复合年增长率为8.41%。这是由于智慧家庭设备、穿戴式健康监测器和娱乐设备等家用电子电器产品的使用日益增长,这些产品促进了远端互动、娱乐和生产力。

- 电动车需求的不断增长和贸易政策的积极变化预计将成为美国汽车工程塑胶市场成长的最大驱动力。就以金额为准,预测期内汽车产业对工程塑胶的需求预计将以 5.31% 的复合年增长率成长。

美国工程塑胶市场趋势

家用电子电器的增加导致电气电子产品生产收入增加

- 技术创新的快速步伐、可支配收入的增加、对高端产品的需求的增加以及生活水准的提高是推动电气和电子市场成长的一些关键因素。 2017年,美国约占北美电气电子设备生产市场的85.9%。

- 2020年,由于政府实施大规模封锁以及封锁造成的供应链中断,该国电气和电子设备产量较去年与前一年同期比较下降约3.3%。受疫情影响,2020年美国国内电子及家用电子电器产品销售额下降9.9%。不过,2021年美国家用电子电器产业销售额达到约1,270亿美元,与前一年同期比较成长9%。因此,2021年全国电气电子设备产量与前一年同期比较增17.1%。

- 预计在预测期内,对智慧型手机、笔记型电脑、个人电脑和电视等技术先进的家用电子电器和小工具的需求激增将推动对家用电子电器的需求。该国消费电子市场规模预计将从2023年的1,551亿美元成长到2027年的约1,613亿美元。对现有家用电子电器产品的探索、技术的不断进步以及新模式的创新正在推动电子市场的成长。因此,预计该国电气和电子产品产量将会成长。

美国工程塑胶产业概况

美国工程塑胶市场相当集中,前五大公司占66.72%的市场。该市场的主要企业包括 Alfa SAB de CV、Ascend Performance Materials、Indorama Ventures Public Company Limited、Koch Industries, Inc.、SABIC 等。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章执行摘要和主要发现

第二章 报告要约

第三章 引言

- 研究假设和市场定义

- 研究范围

- 调查方法

第四章 产业主要趋势

- 最终用户趋势

- 航太

- 车

- 建筑与施工

- 电气和电子

- 包装

- 进出口趋势

- 价格趋势

- 回收概述

- 聚酰胺(PA)回收趋势

- 聚碳酸酯(PC)回收趋势

- 聚对苯二甲酸乙二醇酯(PET)的回收趋势

- 苯乙烯共聚物(ABS、SAN)的回收趋势

- 法律规范

- 美国

- 价值炼和通路分析

第五章市场区隔

- 最终用户产业

- 航太

- 车

- 建筑与施工

- 电气和电子

- 工业/机械

- 包装

- 其他的

- 树脂类型

- 氟树脂

- 依亚型

- 乙烯-四氟乙烯(ETFE)

- 氟化乙丙烯 (FEP)

- 聚四氟乙烯(PTFE)

- 聚氟乙烯(PVF)

- 聚二氟亚乙烯(PVDF)

- 其他子树脂类型

- 液晶聚合物(LCP)

- 聚酰胺(PA)

- 依树脂类型分

- 芳香聚酰胺

- 聚酰胺(PA)6

- 聚酰胺(PA)66

- 聚邻苯二甲酰胺

- 聚丁烯对苯二甲酸酯(PBT)

- 聚碳酸酯(PC)

- 聚醚醚酮(PEEK)

- 聚对苯二甲酸乙二醇酯(PET)

- 聚酰亚胺(PI)

- 聚甲基丙烯酸甲酯(PMMA)

- 聚甲醛(POM)

- 苯乙烯共聚物(ABS和SAN)

- 氟树脂

第六章 竞争格局

- 关键策略趋势

- 市场占有率分析

- 商业状况

- 公司简介.

- Alfa SAB de CV

- Arkema

- Ascend Performance Materials

- BASF SE

- Celanese Corporation

- Covestro AG

- DuPont

- Formosa Plastics Group

- Indorama Ventures Public Company Limited

- INEOS

- Koch Industries, Inc.

- RTP Company

- SABIC

- Solvay

- The Chemours Company

第七章:CEO面临的关键策略问题

第 8 章 附录

- 世界概况

- 概述

- 五力分析框架(产业吸引力分析)

- 全球价值链分析

- 市场动态(DRO)

- 资讯来源及延伸阅读

- 图片列表

- 关键见解

- 资料包

- 词彙表

The United States Engineering Plastics Market size is estimated at 14.96 billion USD in 2024, and is expected to reach 20.47 billion USD by 2029, growing at a CAGR of 6.48% during the forecast period (2024-2029).

Rising adoption of advanced materials to drive the demand for engineering plastics

- Engineering plastics have applications ranging from interior wall panels and doors in aerospace to rigid and flexible packaging. Engineering plastics are popular in many industries due to their lightweight and high quality in terms of strength, low fatigue, and low flammability. The US engineering plastics market is led by industries such as packaging, electrical and electronics, and automotive.

- In the United States, the packaging industry holds the largest market revenue share, which is expected to grow by 5.93% over the forecast period. The demand for plastic packaging is increasing mainly from the food and beverages industry. Moreover, increasing demand for ready-to-eat meals, online food purchasing, etc., has triggered the packaging industry in the country. United States plastic packaging production had a volume of 178 thousand tons in 2022. The demand for engineering plastics in the packaging industry increased at a rate of 7.71% by value in 2022 compared to 2021.

- The electrical and electronics industry in the United States is the second most promising market for engineering plastics, with an expected CAGR of 8.41% by value during the forecast period (2023-2029). This is due to the wider use of consumer electronics products such as smart home devices, wearable health monitors, and entertainment devices to facilitate remote interaction, entertainment, and productivity.

- The rise in demand for electric vehicles and positive changes in trade policies are expected to be the biggest driving factors in the growth of the market for US automotive engineering plastics. The demand for engineering plastic from the automotive industry is expected to record a CAGR of 5.31% by value during the forecast period.

United States Engineering Plastics Market Trends

Rising consumer electronics to augment the electrical & electronics production revenue

- The rapid pace of technological innovation, rising disposable income, increased demand for luxury products, and improving living standards are some of the major factors driving the growth of the electrical and electronics market. In 2017, the United States accounted for around 85.9% of the North American electrical and electronics production market.

- In 2020, the electrical and electronics production in the country decreased by around 3.3% in revenue compared to the previous year, owing to widespread lockdowns implemented by the government and supply chain disruptions caused by these lockdowns. The pandemic resulted in a decline in sales of electronics and appliances in the country by 9.9% in 2020. However, in 2021, consumer electronics industry sales in the United States reached around USD 127 billion, a 9% increase compared to the previous year. Consequently, in 2021, electrical & electronics production in the country grew by a rate of 17.1% in revenue compared to the previous year.

- The surge in demand for technologically advanced consumer electronics and appliances, such as smartphones, laptops, computers, televisions, and others, is expected to boost consumer electronics demand during the forecast period. Consumer electronics in the country are projected to generate a market volume of approximately USD 161.3 billion in 2027, up from USD 155.10 billion in 2023. The increasing research and technological advancements in existing appliances, as well as the innovation of new models, are driving the growth of the electronics market. As a result, the electrical and electronic production in the country is expected to grow.

United States Engineering Plastics Industry Overview

The United States Engineering Plastics Market is fairly consolidated, with the top five companies occupying 66.72%. The major players in this market are Alfa S.A.B. de C.V., Ascend Performance Materials, Indorama Ventures Public Company Limited, Koch Industries, Inc. and SABIC (sorted alphabetically).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY & KEY FINDINGS

2 REPORT OFFERS

3 INTRODUCTION

- 3.1 Study Assumptions & Market Definition

- 3.2 Scope of the Study

- 3.3 Research Methodology

4 KEY INDUSTRY TRENDS

- 4.1 End User Trends

- 4.1.1 Aerospace

- 4.1.2 Automotive

- 4.1.3 Building and Construction

- 4.1.4 Electrical and Electronics

- 4.1.5 Packaging

- 4.2 Import And Export Trends

- 4.3 Price Trends

- 4.4 Recycling Overview

- 4.4.1 Polyamide (PA) Recycling Trends

- 4.4.2 Polycarbonate (PC) Recycling Trends

- 4.4.3 Polyethylene Terephthalate (PET) Recycling Trends

- 4.4.4 Styrene Copolymers (ABS and SAN) Recycling Trends

- 4.5 Regulatory Framework

- 4.5.1 United States

- 4.6 Value Chain & Distribution Channel Analysis

5 MARKET SEGMENTATION (includes market size in Value in USD and Volume, Forecasts up to 2029 and analysis of growth prospects)

- 5.1 End User Industry

- 5.1.1 Aerospace

- 5.1.2 Automotive

- 5.1.3 Building and Construction

- 5.1.4 Electrical and Electronics

- 5.1.5 Industrial and Machinery

- 5.1.6 Packaging

- 5.1.7 Other End-user Industries

- 5.2 Resin Type

- 5.2.1 Fluoropolymer

- 5.2.1.1 By Sub Resin Type

- 5.2.1.1.1 Ethylenetetrafluoroethylene (ETFE)

- 5.2.1.1.2 Fluorinated Ethylene-propylene (FEP)

- 5.2.1.1.3 Polytetrafluoroethylene (PTFE)

- 5.2.1.1.4 Polyvinylfluoride (PVF)

- 5.2.1.1.5 Polyvinylidene Fluoride (PVDF)

- 5.2.1.1.6 Other Sub Resin Types

- 5.2.2 Liquid Crystal Polymer (LCP)

- 5.2.3 Polyamide (PA)

- 5.2.3.1 By Sub Resin Type

- 5.2.3.1.1 Aramid

- 5.2.3.1.2 Polyamide (PA) 6

- 5.2.3.1.3 Polyamide (PA) 66

- 5.2.3.1.4 Polyphthalamide

- 5.2.4 Polybutylene Terephthalate (PBT)

- 5.2.5 Polycarbonate (PC)

- 5.2.6 Polyether Ether Ketone (PEEK)

- 5.2.7 Polyethylene Terephthalate (PET)

- 5.2.8 Polyimide (PI)

- 5.2.9 Polymethyl Methacrylate (PMMA)

- 5.2.10 Polyoxymethylene (POM)

- 5.2.11 Styrene Copolymers (ABS and SAN)

- 5.2.1 Fluoropolymer

6 COMPETITIVE LANDSCAPE

- 6.1 Key Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Landscape

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and Analysis of Recent Developments).

- 6.4.1 Alfa S.A.B. de C.V.

- 6.4.2 Arkema

- 6.4.3 Ascend Performance Materials

- 6.4.4 BASF SE

- 6.4.5 Celanese Corporation

- 6.4.6 Covestro AG

- 6.4.7 DuPont

- 6.4.8 Formosa Plastics Group

- 6.4.9 Indorama Ventures Public Company Limited

- 6.4.10 INEOS

- 6.4.11 Koch Industries, Inc.

- 6.4.12 RTP Company

- 6.4.13 SABIC

- 6.4.14 Solvay

- 6.4.15 The Chemours Company

7 KEY STRATEGIC QUESTIONS FOR ENGINEERING PLASTICS CEOS

8 APPENDIX

- 8.1 Global Overview

- 8.1.1 Overview

- 8.1.2 Porter's Five Forces Framework (Industry Attractiveness Analysis)

- 8.1.3 Global Value Chain Analysis

- 8.1.4 Market Dynamics (DROs)

- 8.2 Sources & References

- 8.3 List of Tables & Figures

- 8.4 Primary Insights

- 8.5 Data Pack

- 8.6 Glossary of Terms