|

市场调查报告书

商品编码

1692443

电力驱动:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Electric Drives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

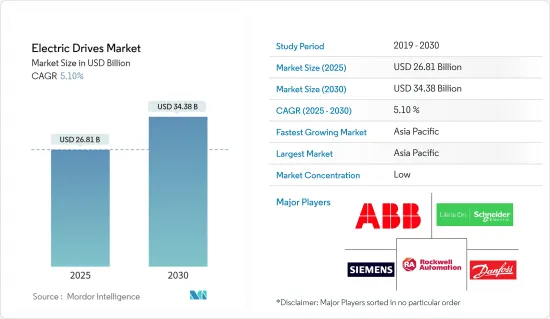

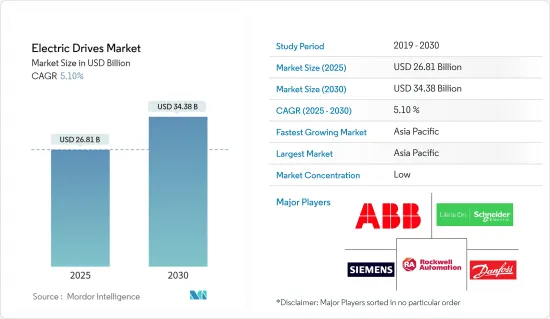

预计 2025 年电力驱动市场规模为 268.1 亿美元,到 2030 年将达到 343.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.1%。

电力驱动器是用来控制马达功率输出的装置。与内燃机或液压系统等传统机械驱动系统相比,它具有多种优势。这些设备效率高,振动和噪音小,并能对马达性能进行精确控制,使电力驱动成为对能源效率、精度和环保至关重要的应用的理想选择。

主要亮点

- 快速的技术进步正在提高多个行业对驱动器的接受度。这项进步的重点是高可靠性和降低能源成本,配备马达驱动系统的商业建筑每平方英尺的能源消耗可能减少 30-40%。现代先进的驱动器还整合了网路和诊断功能,以提供更好的性能和更高的生产力。智慧马达控制、降低尖峰电流和节省能源是选择电力驱动器作为任何马达驱动系统控制器的主要原因。

- 这个市场也越来越重视流程优化。在石油和天然气行业,电力驱动可以减少停机时间,因为燃气涡轮机需要频繁维护,而电力驱动和马达几乎不需要维护。这可以提高产量、降低维护成本并提高生产力。这导致各石油和天然气公司转向电力驱动。

- 能源效率已成为联邦监管机构和产业组织关注的重点。根据国际能源总署 (IEA) 的数据,马达消耗了电力产业所用能源的 40%。当这些马达与电力驱动装置一起用于离心负载服务时,其效率会提高。电力电子技术的技术改进有望提高驱动性能并有助于节约能源。

- 在现有马达上添加电力驱动装置会带来一些技术挑战,这些挑战对各行各业的许多公司都造成了采用障碍。将驱动器改装到现有马达后,马达轴转速会降低,导致轴驱动风扇的冷却效果降低。马达中的转子非常敏感,旋转过于频繁可能会损坏。这是由于激进的动态煞车而发生的。如果转子以这种方式停止,其热膨胀将产生将转子轴拉离定子的力,从而导致轴承故障。这通常发生在 VSD 未充分冷却时。

- 在 COVID-19 疫情期间,所研究的市场成长逐渐增加,因为世界各国政府透过提供资金来扩展汽车、家电、电力、能源和公用事业等各种终端用户产业的晶片,从而推动了基于半导体的电子和公共产业产业的发展。政府也帮助半导体製造商将生产转移出中国,以避免供应链中断。

电力驱动市场趋势

主要终端用户产业是发电

- 电力驱动是节约能源、提高性能、简化系统和减少核子反应炉停机时间的关键。例如,在需要高速液体通道来冷却核子反应炉堆芯的运作过程中,通常有四个大型6kV再循环泵和超过100个控制阀同时运作。此因素约占核能发电厂营运能源成本的25%。

- 这证实了在核能发电产业中使用电力驱动的重要性。田纳西河谷核能发电厂透过从马达技术转向电力驱动,效率从 70% 提高到 95%。使用电力驱动可以减少 50% 的电费,同时降低二氧化碳排放。

- 此外,透过确保不间断的水循环,驱动技术的应用有助于工厂保护易受湍流影响的燃料棒和核燃料。这方面的规定非常严格。最好逐渐增加电力输送,这可以透过仔细控制交流和直流驱动器来实现。希望此举能为法国、英国等国家创造新的商机。核能发电厂生产了法国三分之二以上的电力。

- 据估计,马达约占工业用电量的65%,因此低压马达在工业领域的节能潜力巨大。消费量取决于马达的额定功率、负载和运转时间。因此,高效能低压马达可以在减少二氧化碳排放方面发挥重要作用。

能源需求正在稳定成长。同时,减少能源消耗、降低二氧化碳排放、确保电力供应安全的压力也越来越大。据埃克森美孚公司称,到 2040 年,全球电力需求将达到约 35.3 拍瓦时。预计这将在预测期内推动市场成长。

预计亚太地区成长最快

- 由于最终用户产业的快速成长,亚太地区对研究市场的成长做出了重大贡献,这些产业主要是石油和天然气、用水和污水、化学和石化、食品和饮料、发电、暖通空调、纸浆和造纸、离散製造业等。

- 预计工业和製造业的成长,尤其是中国、印度和台湾等国家的工业和製造业的成长将在预测期内推动对交流电驱动器的需求。例如,根据印度银行联合会(IBEF)的数据,2022 年 1 月印度天然气产量增加 11.7%,精製产量增加 3.7%,煤炭产量增加 8.2%,钢铁产量增加 2.8%,水泥产量增加 13.6%,电力产量增加 0.5%。

- 由于对上游和中游石油和天然气行业的投资增加,预计预测期内交流变频器市场将会成长。此外,上游石油天然气公司正在逐步投资石油生产活动,这将提高交流马达的更换率并促进市场成长。此外,2022 年 5 月,印度石油天然气公司宣布计划在 2022 至 2025 财年期间投资 40 亿美元,加强其在印度的探勘活动。

- 此外,中阶的经济成长对印度的汽车需求有重大影响。例如,根据FADA(汽车经销商协会联合会)的数据,2022年该国售出约21,124,410辆乘用车和拖拉机,与前一年同期比较去年同期成长约15.28%。此外,近年来,塔塔汽车、马恆达、铃木、巴贾杰等公司的销量都大幅成长,本土汽车製造商也正在崭露头角。为了参与全球竞争,这些公司正在大力投资自动化生产线并扩大製造地,推动对电力驱动的需求。

- 韩国是一个高度都市化、人均所得较高的国家。由于中产阶级人口的增长以及住宅、商业和其他建筑数量的增加,该国对 HVAC 系统的需求正在增加。这些系统使用电力驱动来执行马达控制等应用,因此该领域的成长将在预测期内推动对电力驱动的需求。

- 儘管东南亚国家电驱动市场的成长速度不如亚太地区其他主要国家,但近期的经济趋势和各产业的发展正在为所研究的市场创造机会。泰国、印尼等东南亚国家的工业和製造业也正在经历显着成长。例如,泰国和印尼是该地区领先的汽车製造商之一。由于马达和发电机广泛应用于汽车产业的自动化生产线,预计预测期内对电力驱动的需求将会成长。

电力驱动产业概况

电力驱动市场高度分散,主要参与者包括 ABB 有限公司、西门子股份公司、丹佛斯、罗克韦尔自动化公司和施耐德电气股份有限公司。市场上的公司正在采用伙伴关係、创新和收购等策略来加强其产品供应并获得永续的竞争优势。

2023年5月,西门子推出SINAMICS S200伺服驱动系统。其精确的伺服驱动、强大的伺服马达和易于使用的电线提供了高动态性能。新型伺服驱动系统特别适用于需要速度和扭力精度的应用,例如电池製造和电池组装中使用的捲绕机和放捲机。

2023年3月,ABB推出了一款中压VFD(变频器),额定容量为400至1,000 kV,电压高达6.9 kV。风冷式 ACS2000 VFD(变频驱动器)专门用于水泥、采矿、冶金、纸浆和造纸、电力、水、化学和石油和天然气行业的风扇、压缩机、泵浦和其他公共设施应用。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 评估主要宏观经济趋势的影响

第五章市场动态

- 市场驱动因素

- 工业化进程加快,电力驱动在主要产业的应用日益广泛

- 对能源效率的需求不断增加

- 市场限制

- 设备的技术问题

- 设备高成本

第六章市场区隔

- 按产品

- 交流变频器

- 直流驱动

- 伺服驱动器

- 按电压

- 低电压驱动器(<372.8KW 或 <1KV)

- 嵌入式

- 独立

- 中压驱动器(>=372.8KW 或 >=1KW)

- 低电压驱动器(<372.8KW 或 <1KV)

- 按额定功率统计

- 小于250千瓦

- 251~500 kw

- 超过500千瓦

- 按最终用户产业

- 石油和天然气

- 用水和污水

- 化工和石化

- 饮食

- 发电

- 空调

- 纸浆和造纸

- 离散製造业

- 其他最终用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 义大利

- 英国

- 法国

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 其他亚太地区

- 拉丁美洲

- 巴西

- 墨西哥

- 其他拉丁美洲

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东和非洲地区

- 北美洲

第七章竞争格局

- 公司简介

- ABB Ltd.

- Siemens AG

- Danfoss

- Rockwell Automation Inc.

- Schneider Electric SE

- Yaskawa Electric Corporation

- Mitsubishi Electric Corporation

- Nidec Corporation

- SEW-EURODRIVE GmbH & Co. KG

- TMEIC Corporation

第 8 章供应商市场占有率

第九章 市场展望

The Electric Drives Market size is estimated at USD 26.81 billion in 2025, and is expected to reach USD 34.38 billion by 2030, at a CAGR of 5.1% during the forecast period (2025-2030).

An electric drive is a device used to control the output of a motor. It offers several advantages over traditional mechanical drive systems like internal combustion engines or hydraulic systems. These devices are more efficient, produce less vibration and noise, and allow for precise control of motor performance, making electric drives ideal for applications where more energy efficiency, accuracy, and environmental considerations are essential factors.

Key Highlights

- Rapid technological progress has led to the higher acceptability of drives in several industries. The advances focus on high reliability and reduced energy costs, potentially reducing the per-square-foot energy by 30-40% when equipped with motor-driven systems in commercial buildings. The advanced and modern drives also integrate networking and diagnostic capabilities into better performance and improved productivity. Intelligent motor control, reduction of peak-current drawn, and energy savings are significant reasons to choose an electric drive as the controller in every motor-driven system.

- The market is also witnessing an increased focus on process optimization. An electric drive reduces downtime in the oil and gas industry because the gas turbines require frequent maintenance, while electric drives and motors require very little maintenance. This enables more production, lower maintenance expense, and improved productivity. This has encouraged various oil and gas companies to incorporate electric drives.

- Energy efficiency has been of key focus for federal regulators and industry organizations. According to the International Energy Agency, electric motors consume 40% of the energy used in power industries. When these motors are deployed with electric drives in centrifugal load service, their efficiency increases. With the technological improvements in power electronics technology, drives' performance is expected to improve, helping conserve energy.

- The addition of electric drives in existing motors gives rise to several technical problems, which have created a barrier to adoption among numerous players in various industries. After integrating the drive with an existing motor, the speed of the motor shaft reduces, which causes decreased cooling from the shaft-driven fan. The rotors in the electric drive motors are very sensitive and can get damaged by frequent spinning. This occurs because of aggressive dynamic braking. When the rotors are stopped this way, the thermal expansion of the rotor produces a force that pulls the rotor shaft away from the stator, leading to bearing failure. This usually occurs when the VSD is not adequately cooled.

- Growth in the market studied gradually increased during the COVID-19 pandemic because many governments worldwide pushed the semiconductor-based electronics and automation industry by providing funds to expand chips for various end-user industries, especially automobiles, consumer electronics, power, energy, and utilities. Moreover, governments helped semiconductor manufacturers shift their production facilities outside China to avoid supply chain disruption.

Electric Drives Market Trends

Power Generation to be the Major End-user Industry

- Electric drives are critical in saving energy, improving performance, simplifying a system, and cutting downtime in nuclear reactors. For instance, during operations, when the fast passage of liquid is required to cool down the reactor core, it is usual to have four big 6 kV recirculation pumps and more than 100 control values operating simultaneously. This factor accounts for around 25% of the energy costs of running a nuclear power plant.

- This supports the significance of using electric drives in the nuclear power industry. A nuclear power plant in the Tennessee Valley increased its efficiency from 70% to 95% by switching from motor technology to electric drives. Electricity costs can be cut by 50% when drives are used while reducing CO2 emissions.

- Furthermore, by ensuring uninterrupted water circulation, drive technology applications help the plants protect the fuel rods and nuclear fuel, both vulnerable to turbulence. In this regard, the rules are very strict. It is best to increase the electricity supply gradually, which can be done by carefully controlling AC and DC drives. In nations like France and the United Kingdom, new opportunities are anticipated to result from this. Nuclear power plants produce more than two-thirds of the electricity in France.

- Also, it has been estimated that electric motors account for about 65% of the electricity consumed in industrial applications; hence, the energy-saving potential of low-voltage motors in industries is enormous. Energy consumption depends on the motor's kW rating, loading, and hours run. Therefore, high-efficiency low-voltage motors, as such, can play a significant role in reducing CO2 emissions.

Energy demand is rising steadily. At the same time, pressure to reduce energy consumption, lower carbon dioxide (CO2) emissions, and provide secure power supplies is becoming more reliable. According to Exxon Mobil, worldwide electricity demand will reach around 35.3 petawatt hours by 2040. It is expected to drive market growth over the forecast period.

Asia Pacific Expected to be the Fastest Growing Region

- The Asia-Pacific region is significantly investing in the studied market's growth, primarily due to the rapidly growing end-user industries such as oil and gas, water and wastewater, chemical and petrochemical, food and beverage, power generation, HVAC, pulp and paper, discrete industries, and many others in the studied market.

- The growth of the industrial and manufacturing sectors, especially across countries such as China, India, and Taiwan, is expected to drive the demand for AC electric drives during the forecast period. For instance, according to IBEF, in India, outputs increased for natural gas by 11.7%, petroleum refinery production by 3.7%, coal by 8.2%, steel by 2.8%, cement by 13.6%, and electricity by 0.5% in January 2022.

- With increased investments in the oil and gas upstream and midstream sectors, the AC drive market is expected to grow during the forecast period. Furthermore, oil and gas upstream companies are gradually investing in oil production activities, which will increase the replacement rate of AC electric motors, supporting market growth. In addition, in May 2022, the ONGC announced plans to invest USD 4 billion from FY22-25 to increase its exploration efforts in India.

- Furthermore, the economic growth of the middle class has significantly impacted the demand for automobiles in India. For instance, according to the Federation of Automobile Dealers Association (FADA), about 2,11,20,441 passenger vehicles and tractors were sold in the country in 2022, reporting a growth of about 15.28% year-on-year. Furthermore, in recent years, local automobile manufacturers have enhanced their presence, with companies like Tata Motors, Mahindra, Suzuki, and Bajaj significantly expanding their sales figures. To compete with global players, these companies are investing significantly in automated production lines and expanding their manufacturing footprint, driving the demand for electric drives.

- South Korea is a highly urbanized country with a high per capita income. Due to a rising middle-class population and an increasing number of houses, commercial buildings, and other structures, the demand for HVAC systems has been increasing in the country. As these systems use electric drives for applications such as motor control, the growth of the sector will drive the demand for electric drives during the forecast period.

- Although the growth of the electric drives market in Southeast Asian countries has not been at par with other major countries in the Asia-Pacific region, in recent years, the area's economic development and various industries' development have created opportunities in the studied market. The industrial and manufacturing sector is also witnessing notable growth in Southeast Asian countries such as Thailand and Indonesia. For instance, Thailand and Indonesia are among the leading automobile manufacturers in the region. As motors and generators are widely used in automated production lines of the automotive industry, the demand for electric drives is expected to grow during the forecast period.

Electric Drives Industry Overview

The electric drives market is highly fragmented, with major players like ABB Ltd, Siemens AG, Danfoss, Rockwell Automation Inc., and Schneider Electric SE. Players in the market are adopting strategies such as partnerships, innovations, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

In May 2023, Siemens launched the SINAMICS S200 servo drive system, designed for many common applications in electronics, batteries, and other sectors. Its accurate servo drive, strong servo motors, and simple-to-use wires provide high dynamic performance. The new servo drive system is especially useful for applications that need accuracy in speed and torque, such as winding and unwinding machines used in battery manufacture and cell assembly.

In March 2023, ABB launched a medium-voltage VFD (Variable-frequency Drive) with a rated capacity of 400 to 1,000kV and a voltage of up to 6.9kV, appropriate for a broad range of applications without a unique engineering design. The air-cooled ACS2000 VFD (Variable-frequency Drive) was especially used for fans, compressors, pumps, and other public applications in cement, mining and mining, metallurgy, pulp and paper, electric power, water, chemical, oil, and gas industries.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 An Assessment of the Impact of Key Macroeconomic Trends

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rapid Industrialization and Increased use of Electric Drives Across Major Vertical Industries

- 5.1.2 Growing Demand for Energy Efficiency

- 5.2 Market Restraints

- 5.2.1 Technical Concerns of the Equipment

- 5.2.2 High Cost of the Equipment

6 MARKET SEGMENTATION

- 6.1 By Product

- 6.1.1 AC Drives

- 6.1.2 DC Drives

- 6.1.3 Servo Drives

- 6.2 By Voltage

- 6.2.1 Low-Voltage Drive (<372.8KW or <1KV)

- 6.2.1.1 Embedded

- 6.2.1.2 Standalone

- 6.2.2 Medium-Voltage Drive (>=372.8KW or >= 1KW)

- 6.2.1 Low-Voltage Drive (<372.8KW or <1KV)

- 6.3 By Power Rating Statistics

- 6.3.1 <250 KW

- 6.3.2 251 - 500 KW

- 6.3.3 >500 KW

- 6.4 By End-user Industry

- 6.4.1 Oil and Gas

- 6.4.2 Water and Wastewater

- 6.4.3 Chemical and Petrochemical

- 6.4.4 Food and Beverage

- 6.4.5 Power Generation

- 6.4.6 HVAC

- 6.4.7 Pulp and Paper

- 6.4.8 Discrete Industries

- 6.4.9 Other End-user Industries

- 6.5 By Geography

- 6.5.1 North America

- 6.5.1.1 United States

- 6.5.1.2 Canada

- 6.5.2 Europe

- 6.5.2.1 Germany

- 6.5.2.2 Italy

- 6.5.2.3 United Kingdom

- 6.5.2.4 France

- 6.5.2.5 Rest of Europe

- 6.5.3 Asia-Pacific

- 6.5.3.1 China

- 6.5.3.2 Japan

- 6.5.3.3 India

- 6.5.3.4 South Korea

- 6.5.3.5 Rest of Asia-Pacific

- 6.5.4 Latin America

- 6.5.4.1 Brazil

- 6.5.4.2 Mexico

- 6.5.4.3 Rest of Latin America

- 6.5.5 Middle East and Africa

- 6.5.5.1 United Arab Emirates

- 6.5.5.2 Saudi Arabia

- 6.5.5.3 Turkey

- 6.5.5.4 Rest of Middle East and Africa

- 6.5.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd.

- 7.1.2 Siemens AG

- 7.1.3 Danfoss

- 7.1.4 Rockwell Automation Inc.

- 7.1.5 Schneider Electric SE

- 7.1.6 Yaskawa Electric Corporation

- 7.1.7 Mitsubishi Electric Corporation

- 7.1.8 Nidec Corporation

- 7.1.9 SEW-EURODRIVE GmbH & Co. KG

- 7.1.10 TMEIC Corporation