|

市场调查报告书

商品编码

1693819

英国工程塑胶:市场占有率分析、产业趋势和成长预测(2024-2029)United Kingdom Engineering Plastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

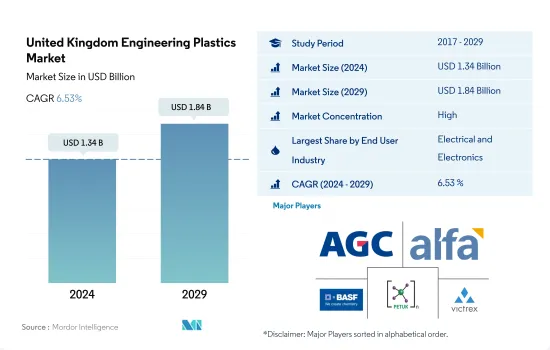

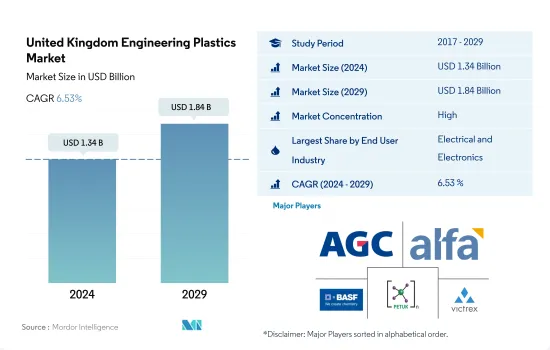

英国工程塑胶市场规模预计在 2024 年达到 13.4 亿美元,预计到 2029 年将达到 18.4 亿美元,预测期内(2024-2029 年)的复合年增长率为 6.53%。

先进材料的应用日益广泛,推动了工程塑胶的需求

- 工程塑料,也称为热塑性聚合物,是一种合成树脂,与传统塑料相比,具有高性能和改进的塑料性能。它在很宽的温度范围内都很稳定,可以承受很大的机械应力和气候变化。

- 包装製造业每年的销售额超过 136 亿美元,这主要得益于食品和饮料、製药、个人保健产品和家居用品等特定行业的高需求。包装产业是该地区最大的工程塑胶消费产业,占2022年工业总消费量的约39%。由于生活方式的不断变化和塑胶包装的多种用途,预计该行业在预测期内的以收益为准年增长率将达到5.73%。

- 电子电气产业是中国工程塑胶的第二大消费产业,占2022年工业总消费量的12%。该产业的发展受到行动电话、电脑、穿戴式装置和电视等家用电子电器产品的推动。例如,预计家用电子电器产业在2023年将创造324.8亿美元的收益。因此,预计该产业工程塑胶的消费量在预测期内将以6.77%的复合年增长率成长。

- 预计航太业在预测期内将达到8.27%的最高成长率。飞机变得更轻、更快的新技术发展正在推动工程塑胶的消费。

英国工程塑胶市场趋势

科技创新推动家用电子电器市场

- 在英国,2020年至2021年间,电气和电子设备产量增加了10.7%。电子产业在英国製造业中发挥重要作用,占整个产业的4.7%。 2017年,附加价值毛额84亿欧元,销售收入为194亿欧元。

- 过去20年,英国电子产业经历了转型,更加重视高科技和密集型的生产流程。该国国家微电子实验室是欧洲最大的独立半导体设计製造商,占专用积体电路设计市场的50%和欧洲所有独立电子设计的40%。这种转变使得英国的电子业务从製造和组装转向了零件设计创新,主要企业的半导体软体设计商 ARM 就是一个突出的例子。

- 电子产品占英国研发製造业总支出的12%以上。前十大出口市场由知名的西方经济体和中国、香港、阿联酋等亚洲新兴市场组成。然而,英国在2019年面临脱欧、美国贸易战、研发资金和网路安全问题等挑战。

- 由于智慧型设备需求不断增长、亚洲市场不断扩大、医疗设备技术进步、节能技术、物联网 (IoT)、5G 技术、虚拟和扩增实境的使用以及自动化,预计该国的电气和电子设备产量将会增加。

英国工程塑胶产业概况。

英国工程塑胶市场相当集中,前五大公司占100%的市场。该市场的主要企业包括 AGC Inc.、Alfa SAB de CV、 BASF SE、Polymer Extruding Technologies (UK) Ltd、Victrex 等。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章执行摘要和主要发现

第二章 报告要约

第三章 引言

- 研究假设和市场定义

- 研究范围

- 调查方法

第四章 产业主要趋势

- 最终用户趋势

- 航太

- 车

- 建筑与施工

- 电气和电子

- 包装

- 进出口趋势

- 价格趋势

- 回收概述

- 聚酰胺(PA)回收趋势

- 聚碳酸酯(PC)回收趋势

- 聚对苯二甲酸乙二醇酯(PET)的回收趋势

- 苯乙烯共聚物(ABS、SAN)的回收趋势

- 法律规范

- 英国

- 价值炼和通路分析

第五章市场区隔

- 最终用户产业

- 航太

- 车

- 建筑与施工

- 电气和电子

- 工业/机械

- 包装

- 其他的

- 树脂类型

- 氟树脂

- 依亚型

- 乙烯-四氟乙烯(ETFE)

- 氟化乙丙烯 (FEP)

- 聚四氟乙烯(PTFE)

- 聚氟乙烯(PVF)

- 聚二氟亚乙烯(PVDF)

- 其他子树脂类型

- 液晶聚合物(LCP)

- 聚酰胺(PA)

- 依树脂类型分

- 芳香聚酰胺

- 聚酰胺(PA)6

- 聚酰胺(PA)66

- 聚邻苯二甲酰胺

- 聚丁烯对苯二甲酸酯(PBT)

- 聚碳酸酯(PC)

- 聚醚醚酮(PEEK)

- 聚对苯二甲酸乙二醇酯(PET)

- 聚酰亚胺(PI)

- 聚甲基丙烯酸甲酯(PMMA)

- 聚甲醛(POM)

- 苯乙烯共聚物(ABS和SAN)

- 氟树脂

第六章竞争格局

- 关键策略趋势

- 市场占有率分析

- 商业状况

- 公司简介

- AGC Inc.

- Alfa SAB de CV

- Asahi Kasei Corporation

- BASF SE

- Celanese Corporation

- Covestro AG

- Domo Chemicals

- INEOS

- Mitsubishi Chemical Corporation

- Polymer Extrusion Technologies (UK) Ltd

- Radici Partecipazioni SpA

- Solvay

- Sumitomo Chemical Co., Ltd.

- Teijin Limited

- Victrex

第七章:CEO面临的关键策略问题

第 8 章 附录

- 世界概况

- 概述

- 五力分析框架(产业吸引力分析)

- 全球价值链分析

- 市场动态(DRO)

- 资讯来源及延伸阅读

- 图片列表

- 关键见解

- 数据包

- 词彙表

简介目录

Product Code: 5000157

The United Kingdom Engineering Plastics Market size is estimated at 1.34 billion USD in 2024, and is expected to reach 1.84 billion USD by 2029, growing at a CAGR of 6.53% during the forecast period (2024-2029).

Rising adoption of advanced materials to drive the demand for engineering plastics

- Engineering plastics, also known as thermoplastic polymers, are a class of synthetic resins that offer high-performance capabilities and improved plastic properties compared to conventional plastics. They exhibit stability over a broad temperature range and can withstand significant mechanical stress and climatic changes.

- The packaging production industry generates annual sales of over USD 13.6 billion, driven by high demand from specific industries such as food and beverage, pharmaceuticals, and personal and household care products. The packaging industry is the largest consumer of engineering plastics in the region, accounting for approximately 39% of total consumption across all industries in 2022. With changing, fast-paced lifestyles and the versatility of plastic packaging, the industry is projected to record a CAGR of 5.73% in terms of revenue during the forecast period.

- The electrical and electronics industry is the second-largest consumer of engineering plastics in the country, representing 12% of total consumption across all industries in 2022. This industry is driven by consumer electronics such as mobile phones, computers, wearables, TVs, and similar products. For example, the consumer electronics industry is expected to generate USD 32.48 billion in revenue in 2023. Consequently, the consumption volume of engineering plastics in this industry is projected to increase at a CAGR of 6.77% during the forecast period.

- The aerospace industry is likely to exhibit the highest growth rate of 8.27% over the forecast period. The development of new technologies for lighter and faster aircraft is driving the consumption of engineering plastics.

United Kingdom Engineering Plastics Market Trends

Technological innovations to boost the consumer electronics market

- The United Kingdom witnessed a revenue increase of 10.7% in electrical and electronics production from 2020 to 2021. The electronics industry holds significant importance in UK manufacturing, accounting for 4.7% of the overall industry. In 2017, it generated EUR 8.4 billion in gross value added and EUR 19.4 billion in turnover.

- Over the past two decades, the electronics industry in the United Kingdom has undergone a transformation, focusing more on high-technology and knowledge-intensive production processes. The country's National Microelectronics Institute is the largest independent semiconductor design producer in Europe, commanding 50% of the market in application-specific integrated circuit design and 40% of Europe's independent electronics design overall. This shift has led to a transition in the UK's electronics activity from manufacturing and assembly to component design and innovation, with ARM, a major semiconductor and software design company, serving as a notable example.

- Electronics contributes more than 12% of the total R&D manufacturing expenditure in the country. The top 10 export markets consist of prominent Western economies, as well as emerging markets in Asia, including China, Hong Kong, and the United Arab Emirates. However, the United Kingdom faced challenges such as Brexit, the US-China trade war, R&D funding, and cybersecurity issues in 2019.

- The country is expected to witness an increase in the production of electrical and electronic equipment due to growing demand for smart devices, the expanding market in Asia, advancements in medical device technology, energy-efficient technologies, the Internet of Things (IoT), 5G technology, the use of virtual and augmented reality, and automation.

United Kingdom Engineering Plastics Industry Overview

The United Kingdom Engineering Plastics Market is fairly consolidated, with the top five companies occupying 100%. The major players in this market are AGC Inc., Alfa S.A.B. de C.V., BASF SE, Polymer Extrusion Technologies (UK) Ltd and Victrex (sorted alphabetically).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY & KEY FINDINGS

2 REPORT OFFERS

3 INTRODUCTION

- 3.1 Study Assumptions & Market Definition

- 3.2 Scope of the Study

- 3.3 Research Methodology

4 KEY INDUSTRY TRENDS

- 4.1 End User Trends

- 4.1.1 Aerospace

- 4.1.2 Automotive

- 4.1.3 Building and Construction

- 4.1.4 Electrical and Electronics

- 4.1.5 Packaging

- 4.2 Import And Export Trends

- 4.3 Price Trends

- 4.4 Recycling Overview

- 4.4.1 Polyamide (PA) Recycling Trends

- 4.4.2 Polycarbonate (PC) Recycling Trends

- 4.4.3 Polyethylene Terephthalate (PET) Recycling Trends

- 4.4.4 Styrene Copolymers (ABS and SAN) Recycling Trends

- 4.5 Regulatory Framework

- 4.5.1 United Kingdom

- 4.6 Value Chain & Distribution Channel Analysis

5 MARKET SEGMENTATION (includes market size in Value in USD and Volume, Forecasts up to 2029 and analysis of growth prospects)

- 5.1 End User Industry

- 5.1.1 Aerospace

- 5.1.2 Automotive

- 5.1.3 Building and Construction

- 5.1.4 Electrical and Electronics

- 5.1.5 Industrial and Machinery

- 5.1.6 Packaging

- 5.1.7 Other End-user Industries

- 5.2 Resin Type

- 5.2.1 Fluoropolymer

- 5.2.1.1 By Sub Resin Type

- 5.2.1.1.1 Ethylenetetrafluoroethylene (ETFE)

- 5.2.1.1.2 Fluorinated Ethylene-propylene (FEP)

- 5.2.1.1.3 Polytetrafluoroethylene (PTFE)

- 5.2.1.1.4 Polyvinylfluoride (PVF)

- 5.2.1.1.5 Polyvinylidene Fluoride (PVDF)

- 5.2.1.1.6 Other Sub Resin Types

- 5.2.2 Liquid Crystal Polymer (LCP)

- 5.2.3 Polyamide (PA)

- 5.2.3.1 By Sub Resin Type

- 5.2.3.1.1 Aramid

- 5.2.3.1.2 Polyamide (PA) 6

- 5.2.3.1.3 Polyamide (PA) 66

- 5.2.3.1.4 Polyphthalamide

- 5.2.4 Polybutylene Terephthalate (PBT)

- 5.2.5 Polycarbonate (PC)

- 5.2.6 Polyether Ether Ketone (PEEK)

- 5.2.7 Polyethylene Terephthalate (PET)

- 5.2.8 Polyimide (PI)

- 5.2.9 Polymethyl Methacrylate (PMMA)

- 5.2.10 Polyoxymethylene (POM)

- 5.2.11 Styrene Copolymers (ABS and SAN)

- 5.2.1 Fluoropolymer

6 COMPETITIVE LANDSCAPE

- 6.1 Key Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Landscape

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and Analysis of Recent Developments).

- 6.4.1 AGC Inc.

- 6.4.2 Alfa S.A.B. de C.V.

- 6.4.3 Asahi Kasei Corporation

- 6.4.4 BASF SE

- 6.4.5 Celanese Corporation

- 6.4.6 Covestro AG

- 6.4.7 Domo Chemicals

- 6.4.8 INEOS

- 6.4.9 Mitsubishi Chemical Corporation

- 6.4.10 Polymer Extrusion Technologies (UK) Ltd

- 6.4.11 Radici Partecipazioni SpA

- 6.4.12 Solvay

- 6.4.13 Sumitomo Chemical Co., Ltd.

- 6.4.14 Teijin Limited

- 6.4.15 Victrex

7 KEY STRATEGIC QUESTIONS FOR ENGINEERING PLASTICS CEOS

8 APPENDIX

- 8.1 Global Overview

- 8.1.1 Overview

- 8.1.2 Porter's Five Forces Framework (Industry Attractiveness Analysis)

- 8.1.3 Global Value Chain Analysis

- 8.1.4 Market Dynamics (DROs)

- 8.2 Sources & References

- 8.3 List of Tables & Figures

- 8.4 Primary Insights

- 8.5 Data Pack

- 8.6 Glossary of Terms

02-2729-4219

+886-2-2729-4219