|

市场调查报告书

商品编码

1567379

FE·先进封装金属化学品市场:2024年~2025年(Critical Materials Report)Metal Chemicals for FE & Advanced Packaging Market Report 2024-2025 (Critical Materials Report) |

||||||

价格

本报告调查了FE/先进封装的金属化学品市场,并提供了应用于先进封装(晶圆级)和半导体装置製造(镶嵌製程)的金属化学品市场的趋势和供应链信息,内容非常全面。铜电镀和添加剂趋势、市场占有率、技术趋势和供应商概况。附录中还包括供应商产品比较图,总结了先进封装中使用的电镀产品的公开资讯。

资讯图表

目录

第1章 摘要整理

第2章 调查范围,目的,手法

第3章 半导体产业的市场预测

- 全球经济与整个产业的展望

- 以电子产品细分市场划分的晶片销售额

- 半导体製造业的成长与扩张

- 政策和贸易趋势及影响

- 半导体材料概述

第4章 各市场区隔金属化学品市场

- 定义

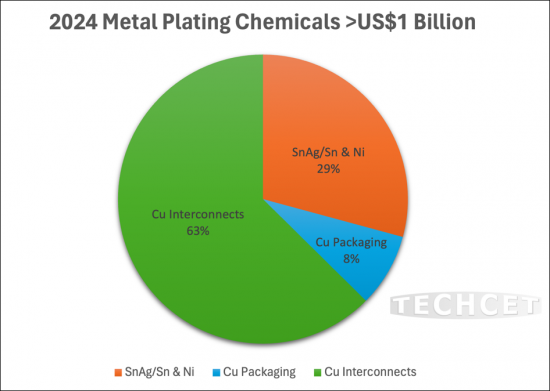

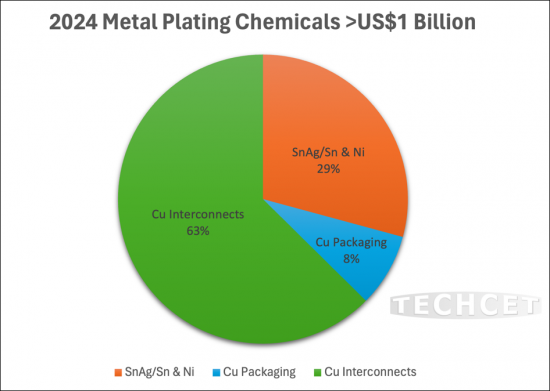

- 金属电镀化学品市场概览

- 先进封装金属化 - 市场推动因素

- 晶片互连成长趋势

- 电镀化学品金属矿的位置

- IC电镀中使用的金属的潜在瓶颈

- 未来可能面临的需求价格压力

第5章 技术趋势

- 半导体金属镀金所使用的化学物质

- 封装技术趋势

- 技术趋势

第6章 竞争情形

- 先进封装与互连市场占有率总计

- OEM市占率-电镀设备

- 按应用划分的市场占有率 - 用于先进封装的 CU 电镀

- 区域进入者和其他人

- 併购活动

第7章 分析师的评估

- 先进的金属镀金的应用市场评估

第8章 供应商简介

- BASF

- DUPONT

- CHANG CHUN GROUP

- INCHEON CHEMICAL COMPANY

- ISHIHARA CHEMICAL/UNICON

- 其他9公司

第9章 附录A:封装技术趋势

- 科技的课题

- 金属清洁面临的挑战

- 市场趋势

- 晶圆级电镀 - 第一级互连

- 先进封装应用的市场推动因素

- 晶圆级封装架构

- 技术趋势-RDL

- 小晶片架构的市场推动因素

- TSV 填充 2.5-3D

- 包装电镀要求

This report covers the Metal Chemicals market trends and supply-chain as it applied to Advanced Packaging (wafer level) and Semiconductor Device Manufacturing (damascene process). Included are forecasts for copper plating and additives, market shares, technical trends, and supplier profiles. Also included in the appendix is a supplier product comparison table of publicly available information on plating products used for advanced packaging.

INFOGRAPHICS

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY

- 1.1 EXECUTIVE SUMMARY

- 1.2 ADVANCED PACKAGING PER WAFER STARTS

- 1.3 DEVICE DEMAND DRIVERS - LOGIC

- 1.4 CU PLATING FORECAST FOR CU INTERCONNECTS AND ADVANCED PACKAGING

- 1.5 MARKET SHARES

- 1.6 SUPPLIER ACTIVITIES - VARIOUS ANNOUNCEMENTS

- 1.7 RISK FACTORS

- 1.8 ANALYST ASSESSMENT

2 SCOPE, PURPOSE AND METHODOLOGY

- 2.1 SCOPE

- 2.2 PURPOSE & METHODOLOGY

- 2.3 OVERVIEW OF OTHER TECHCET CMR REPORTS

3 SEMICONDUCTOR INDUSTRY MARKET OUTLOOK

- 3.1 WORLDWIDE ECONOMY AND OVERALL INDUSTRY OUTLOOK

- 3.1.1 SEMICONDUCTOR INDUSTRIES TIES TO THE GLOBAL ECONOMY

- 3.1.2 SEMICONDUCTOR SALES GROWTH

- 3.1.3 TAIWAN OUTSOURCE MANUFACTURER MONTHLY SALES TRENDS

- 3.2 CHIPS SALES BY ELECTRONIC GOODS SEGMENT

- 3.2.1 ELECTRONICS OUTLOOK

- 3.2.2 AUTOMOTIVE INDUSTRY OUTLOOK

- 3.2.3 SMARTPHONE OUTLOOK

- 3.2.4 PC OUTLOOK

- 3.2.5 SERVERS / IT MARKET

- 3.3 SEMICONDUCTOR FABRICATION GROWTH & EXPANSION

- 3.3.1 IN THE MIDST OF HUGE INVESTMENT IN CHIP EXPANSIONS

- 3.3.2 NEW FABS IN THE US

- 3.3.3 WW FAB EXPANSION DRIVING GROWTH

- 3.3.4 EQUIPMENT SPENDING TRENDS

- 3.3.5 ADVANCED LOGIC TECHNOLOGY ROADMAPS

- 3.3.6 FAB INVESTMENT ASSESSMENT

- 3.4 POLICY & TRADE TRENDS AND IMPACT

- 3.5 SEMICONDUCTOR MATERIALS OVERVIEW

- 3.5.1 TECHCET WAFER STARTS FORECAST THROUGH 2028

- 3.5.2 TECHCET MATERIALS MARKET FORECAST THROUGH 2028

4 METAL CHEMICALS MARKET BY SEGMENT

- 4.1 DEFINITIONS

- 4.2 METAL PLATING CHEMICALS MARKET OVERVIEW

- 4.2.1 OVERVIEW - CU ADVANCED PACKAGING AND CHIP INTERCONNECTS METALLIZATION

- 4.2.2 OVERVIEW - PLATING MARKET TRANSITIONAL TRENDS

- 4.3 ADVANCED PACKAGING METALLIZATION - MARKET DRIVERS

- 4.3.1 ADVANCED PACKAGING - ADDITIVES FOR CU PLATING REVENUE

- 4.3.2 ADVANCED PACKAGING - COPPER CHEMICALS REVENUE

- 4.3.3 ADVANCED PACKAGING ADDITIVE VOLUMES

- 4.3.4 OTHER PLATING MATERIALS FOR ADVANCED PACKAGING

- 4.3.5 SN / SNAG PLATING

- 4.4 CHIP INTERCONNECTS GROWTH TRENDS

- 4.4.1 CHIP INTERCONNECTS GROWTH DRIVERS

- 4.4.2 CHIP INTERCONNECTS CU PLATING REVENUES

- 4.4.3 CHIP INTERCONNECTS ADDITIVE VOLUMES

- 4.5 MINE LOCATIONS FOR METALS IN PLATING CHEMICALS

- 4.6 POSSIBLE CHOKE POINTS FOR METALS USED IN IC PLATING

- 4.7 FUTURE POSSIBLE DEMAND PRICE PRESSURES

5 TECHNICAL TRENDS

- 5.1 CHEMISTRIES USE FOR SEMICONDUCTOR METAL PLATING

- 5.2 PACKAGING TECH TRENDS

- 5.2.1 PACKAGING TECHNICAL CHALLENGES

- 5.3 TECH TRENDS

- 5.3.1 MARKET DRIVES TECHNOLOGY TRENDS

- 5.3.2 ADV LOGIC INTERCONNECT WIRING TECHNOLOGY EVOLUTION

- 5.3.3 CU INTERCONNECTS QUALIFICATION REQUIREMENTS

- 5.3.4 LOGIC METALLIZATION ROADMAP

- 5.3.5 ADV LOGIC BURIED POWER RAIL

- 5.3.6 TECHNOLOGY ROADMAP: DRAM WITH MO OR RU

- 5.3.7 PRECURSOR TECHNOLOGY ROADMAP: 3D NAND USING MO OR RU

- 5.3.8 EXAMPLE OF LOGIC PRO CESS FLOW 20 NM TO 32 NM LOGIC PVD

- 5.3.9 TECHNICAL REQUIREMENTS SUMMARY 1/2

6 COMPETITIVE LANDSCAPE

- 6.1 TOTAL ADVANCED PACKAGING AND INTERCONNECTS MARKET SHARES

- 6.2 OEM MARKET SHARE - PLATING EQUIPMENT

- 6.3 MARKET SHARE BY APPLICATION - CU PLATING FOR ADVANCED PACKAGING

- 6.4 REGIONAL PLAYERS AND OTHERS

- 6.5 M&A ACTIVITY

7 ANALYST ASSESSMENT

- 7.1 ADVANCED METAL PLATING APPLICATIONS MARKET ASSESSMENT

8 SUPPLIER PROFILES

- BASF

- DUPONT

- CHANG CHUN GROUP

- INCHEON CHEMICAL COMPANY

- ISHIHARA CHEMICAL/UNICON

- ...AND 9 MORE

9 APPENDIX A: PACKAGING TECH TRENDS

- 9.1 TECHNOLOGY CHALLENGE

- 9.1.1 METAL CLEANINGS CHALLENGE

- 9.1.2 MARKET DYNAMIC

- 9.1.3 WAFER LEVEL PLATING-FIRST LEVEL INTERCONNECT

- 9.1.4 MARKET DRIVERS OF ADVANCED PACKAGING APPLICATIONS

- 9.1.5 WAFER LEVEL PACKAGING ARCHITECTURES

- 9.1.6 TECH TRENDS- RDL

- 9.1.7 MARKET DRIVERS OF CHIPLET ARCHITECTURE

- 9.1.8 TSV FILLING 2.5-3D

- 9.1.9 PACKAGING ELECTROPLATING REQUIREMENTS

LIST OF FIGURES

- FIGURE 1.1: PLATING MATERIALS FOR ADVANCED PACKAGING AND INTERCONNECT REVENUES ($M'S)

- FIGURE 1.2. WAFERS/YR & % OF PACKAGING THAT IS ADVANCED PACKAGING (AP)

- FIGURE 1.3: ADV LOGIC DEVICE GROWTH FORECAST

- FIGURE 1.4: COPPER PLATING CHEMICALS REVENUES ($M'S) FOR ADVANCED PACKAGING & FE CU INTERCONNECTS

- FIGURE 1.5: 2023 SUPPLIER MARKET SHARES CU PLATING FOR INTERCONNECT ADDITIVES

- FIGURE 1.6: 2023 SUPPLIER MARKET SHARES CU PLATING FOR ADV. PACKAGING

- FIGURE 3.1: GLOBAL ECONOMY AND THE ELECTRONICS SUPPLY CHAIN (2023)

- FIGURE 3.2: WORLDWIDE SEMICONDUCTOR SALES

- FIGURE 3.3: TECHCET'S TAIWAN SEMICONDUCTOR INDUSTRY INDEX (TTSII) IN 000'S OF NTD

- FIGURE 3.4: 2023 SEMICONDUCTOR CHIP APPLICATIONS

- FIGURE 3.5: GLOBAL LIGHT VEHICLE UNIT SALES

- FIGURE 3.6: ELECTRIFICATION TREND BY WORLD REGION

- FIGURE 3.7: AUTOMOTIVE SEMICONDUCTOR PRODUCTION

- FIGURE 3.8: MOBILE PHONE SHIPMENTS, WW ESTIMATES

- FIGURE 3.9: WORLDWIDE PC AND TABLET FORECAST

- FIGURE 3.9: WORLDWIDE PC AND TABLET FORECAST

- FIGURE 3.10: TSMC PHOENIX CAMPUS WITH THE 2ND FAB VISIBLE IN THE BACKGROUND

- FIGURE 3.11: ESTIMATED GLOBAL FAB SPENDING 2023-2028

- FIGURE 3.12: FAB EXPANSIONS WITHIN THE US

- FIGURE 3.13: SEMICONDUCTOR CHIP MANUFACTURING REGIONS OF THE WORLD

- FIGURE 3.14: GLOBAL TOTAL EQUIPMENT SPENDING (US$ M) AND Y-O-Y CHANGE

- FIGURE 3.15: ADVANCED LOGIC DEVICE TECHNOLOGY ROADMAP OVERVIEW

- FIGURE 3.16: DRAM TECHNOLOGY ROADMAP OVERVIEW

- FIGURE 3.17: 3D NAND TECHNOLOGY ROADMAP OVERVIEW

- FIGURE 3.18: INTEL OHIO PLANT SITE AS OF FEB. 2024

- FIGURE 3.19: TECHCET WAFER START FORECAST BY NODE SEGMENTS

- FIGURE 3.20: TECHCET WORLDWIDE MATERIALS FORECAST ($M USD)

- FIGURE 4.1: PACKAGING METALLIZATION APPLICATIONS

- FIGURE 4.2: USE OF SILICON INTERPOSER IN 2.5D PACKAGING

- FIGURE 4.3: VERSIONS OF TSV & PROCESS FLOW EXAMPLE

- FIGURE 4.4: PLATING MATERIALS FOR ADVANCED PACKAGING AND DEVICE INTERCONNECT REVENUES (M'S)

- FIGURE 4.5: CU PLATING CHEMICALS 5-YEAR FORECAST

- FIGURE 4.6: WAFERS/YR & % OF PACKAGING THAT IS ADVANCED PACKAGING

- FIGURE 4.7: REVENUE FORECAST CU PLATING ADVANCED PACKAGING

- FIGURE 4.8: CU PILLAR & CU RDL SEGMENTED FORECAST

- FIGURE 4.9: ADV. PACKAGING CU CUSO4 AMOUNT DEMAND FORECAST

- FIGURE 4.10: ADV. PACKAGING CU/VMS VOLUME DEMAND FORECAST ADV.PACKAGING CU PLATING ADDITIVES

- FIGURE 4.11: BUMPING MATERIALS FOR FIRST LEVEL INTERCONNECT

- FIGURE 4.12: HYBRID BONDING PROCESS

- FIGURE 4.13: SN AND SNAG PLATING REVENUE

- FIGURE 4.14: NICKEL PLATING REVENUE

- FIGURE 4.15: ADV LOGIC DEVICE GROWTH FORECAST

- FIGURE 4.16: METAL PLATING WAFER PASSES

- FIGURE 4.17: WW DAMASCENE REVENUE FORECAST ESTIMATES

- FIGURE 4.18: DAMASCENE CUSO4 VOLUME DEMAND FORECAST

- FIGURE 4.19: DAMASCENE CU PLATING CHEMICAL AMOUNT DEMAND FORECAST

- FIGURE 5.1: KEY TRENDS IN ADVANCED PACKAGING

- FIGURE 5.2: CHALLENGES OF ELECTROPLATING VIA FILL

- FIGURE 5.3: METAL INTERCONNECTS BY LOGIC NODE

- FIGURE 5.4: INTERCONNECT METAL COMPARISON BY RESISTIVITY

- FIGURE 5.5: CU CHIP INTERCONNECTS QUALIFICATION

- FIGURE 5.6: LEADING EDGE LOGIC POWER RAIL SCHEMES

- FIGURE 5.7: DRAM STRUCTURE

- FIGURE 5.8: 3D NAND STRUCTURE

- FIGURE 6.1: TOTAL PLATING FOR ADV. PACKAGING AND CU INTERCONNECT ADDITIVES 2023

- FIGURE 6.2: PLATING EQUIPMENT OEM MARKET SHARES % 2023

- FIGURE 6.3: PLATING CHEMICAL SUPPLIER FOR INTERCONNECTS AND ADVANCED PACKAGING APPLICATIONS

- FIGURE 9.1: CLEANING COMPLEXITY

- FIGURE 9.2: OSATS PACKAGING BUSINESS CANNIBALIZATION TREND

- FIGURE 9.3: WAFER LEVEL PLATING

- FIGURE 9.4: ADVANCED PACKAGING MARKET DRIVERS AND APPLICATIONS

- FIGURE 9.4: ADVANCED PACKAGING MARKET DRIVERS AND APPLICATIONS

- FIGURE 9.5: FAN-IN (WLCSP) & FAN-OUT (WLFO) COMPARISON

- FIGURE 9.6: RDL CIRCUITRY EXAMPLE

- FIGURE 9.7: COMPARISON WITH DAMASCENE- TYPE RDL

- FIGURE 9.8: COST/PERFORMANCE IMPROVEMENTS THROUGH CHIPLETS INTEGRATION

- FIGURE 9.9: 2.5 AND 3D PACKAGING EXAMPLES

- FIGURE 9.10: USE OF SILICON INTERPOSER

- FIGURE 9.11: TSV PROCESS FLOW EXAMPLE

- FIGURE 9.12: PROCESS COMPARISON OF TRADITIONAL VS. WLP FLOWS

LIST OF TABLES

- TABLE 3.2: BATTERY ELECTRIC VEHICLE (BEV) REGIONAL TRENDS

- TABLE 3.3: DATA CENTER SYSTEMS AND COMMUNICATION SERVICES MARKET SPENDING 2023

- TABLE 5.1: IRDS 2023 MORE MOORE INTERCONNECT ROADMAP

- TABLE 5.2: BARRIER METAL ROADMAP

- TABLE 5.3: METALS REQUIRED FOR DEVICE FEATURES

- TABLE 5.4: DRAM USE OF MO OR RU PRESENT & FUTURE

- TABLE 5.5: GENERAL PROCESS FLOW ADVANCED DRAM

- TABLE 5.5: 3D NAND MATERIAL CHANGES PRESENT & FUTURE

- TABLE 5.6: NUMBER OF STACKS (S) & LAYERS (L) PER GENERATION OF 3DNAND - SOME ARE ESTIMATES FOR THE FUTURE

- TABLE 5.7: EXAMPLE OF LOGIC PROCESS FLOW 20 NM TO 32 NM LOGIC PVD

- TABLE 5.8: TECHNICAL REQUIREMENTS SUMMARY

- TABLE 5.9: TECHNICAL REQUIREMENTS SUMMARY, CONTINUED

- TABLE 6.1: REGIONAL PLAYERS - MARKET LEADER AND "OTHERS"

- TABLE 9.1: CU PACKAGING APPLICATIONS AND REQUIREMENTS

02-2729-4219

+886-2-2729-4219