|

市场调查报告书

商品编码

1636280

英国电动车电池材料:市场占有率分析、产业趋势/统计、成长预测(2025-2030)United Kingdom Electric Vehicle Battery Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

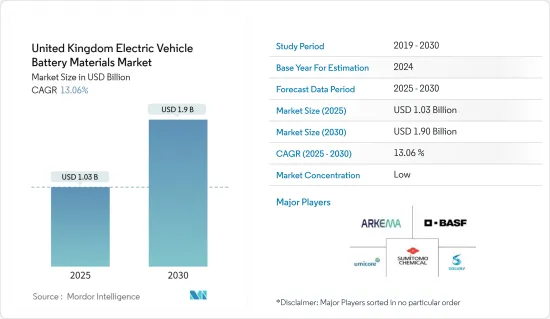

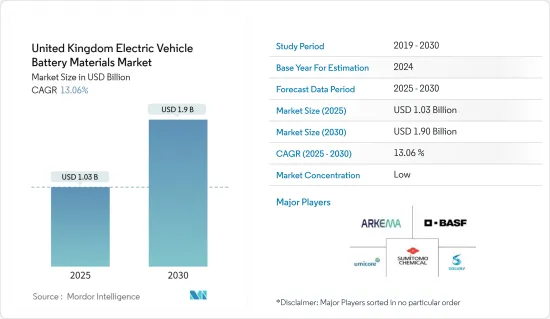

英国电动车电池材料市场规模预计到2025年为10.3亿美元,预计2030年将达到19亿美元,预测期内(2025-2030年)复合年增长率为13.06%。

主要亮点

- 从中期来看,电动车(EV)销售的成长以及政府的支持性措施和法规预计将在预测期内推动电动车电池材料的需求。

- 另一方面,蕴藏量短缺可能会明显抑制电动车电池材料市场的成长。

- 电池技术的进步,如提高能量密度、缩短充电时间、提高安全性和延长使用寿命等,预计将在不久的将来为电动车电池材料市场的参与企业提供重大商机。

英国电动车电池材料市场趋势

电动车 (EV) 销量的成长推动市场

- 在英国(英国),电动车(EV)销量的增加正在推动对电动车电池材料的需求。随着电动车在国内的普及,对锂、钴、镍、石墨等关键电池零件的需求迅速增加。这种需求的增加不仅刺激了当地生产,还吸引了投资并加强了英国电池材料供应链。

- 英国正在协调一致地转向以电动车为中心的清洁能源。近年来,该地区的电动车销量呈现大幅成长。例如,国际能源总署(IEA)报告称,2023年英国电动车销量为45万辆,较2022年成长21.62%。随着英国政府推出多项倡议和计划,电动车销量预计将激增,导致对电池材料的需求增加。

- 英国政府正透过补贴、税收优惠和严格的排放法规积极培育电动车市场。这些倡议不仅支持了电池材料产业,也增加了国家对电动车的需求。政府制定了雄心勃勃的目标,并预计在不久的将来电动车销量将成长四倍。

- 为了证明其承诺,英国已于 2023 年推出了零排放汽车 (ZEV) 指令。该指令规定,到2030年,80%的新车和70%的新车将是零排放汽车,到2035年将全面转型。此外,它将在2030年停止销售新的汽油和柴油汽车,并要求在2035年所有新车实现零排放。这些措施将在未来几年加速电动车的生产和对电池材料的需求。

- 此外,英国电动车的竞争格局正在推动电池技术的创新。当地公司和研究机构正在投资先进材料,以提高能量密度、寿命和安全性。该地区主要企业之间的合作旨在开发尖端的电池解决方案,并预示着未来几年对电动车电池的强劲需求。

- 例如,2024 年 1 月,微软宣布与美国能源局太平洋西北国家实验室 (PNNL) 合作推出突破性材料。这项发现结合了人工智慧 (AI) 和超级运算,预计将电池锂消费量减少 70%。研究人员也强调了显着提高电池效率的潜力,特别是在电动车(EV)和相关领域。这些进步将推动对复杂电动车电池的需求,进而推动该地区的电池材料需求。

- 鑑于这些发展,很明显,英国的倡议和计划不仅将增强对电动车的需求,而且还将在可预见的未来显着增加对电动车电池材料的需求。

锂离子电池占市场主导地位

- 扩大电动车(EV)锂离子电池的生产对电池材料市场有重大影响。锂离子电池製造的激增正在推动对锂的需求,而各个地区发现的锂对原料成本有直接影响。

- 认识到这一趋势,主要市场参与企业正在增加对锂蕴藏量和研发的投资。目的是提高锂离子电池的产量并满足对电池原料不断增长的需求。随着新蕴藏量的发现,锂离子电池的价格正在大幅下降。

- 例如,2023年电池价格大幅下降至139美元/kWh,下降13%。专家预测,随着技术进步和製造效率提高,到2025年将降至113美元/千瓦时,2030年进一步降至80美元/度。

- 为了应对日益严重的环境问题,英国政府正积极推动电动车锂离子电池的生产。为了实现零净碳排放目标,并满足该地区对电动车不断增长的需求,政府正在推出一系列计划来提高锂离子电池的生产。

- 2023年5月,捷豹和路虎的母公司塔塔汽车宣布计划在英格兰西南部萨默塞特建造一座最先进的电动车电池工厂,投资额达数万美元。这些战略倡议预计将加速锂离子电池作为能源来源的采用,并在可预见的未来增加对电池材料的需求。

- 在最近的发展中,英国在开发先进的锂离子电池回收技术方面处于主导。公司和研究机构正在创新有效的方法,从废弃电池中回收锂、钴和镍等有价值的材料。

- 2024 年 3 月,永续电池废弃物回收专家、总部位于英国的 Altilium 宣布与日产建立合作关係。该合作伙伴关係将引入先进的回收技术,以减少英国製造的新型电池的碳足迹,并减少对进口原料的依赖。该倡议是先进推进中心 (APC) 3000 万英镑(3800 万美元)计划的一部分,Altilium 获得了 1500 万英镑(1900 万美元)的巨额津贴。这些倡议不仅将加速锂离子原料的生产,也将增强未来电动车电池材料的生产。

- 鑑于这些进步和倡议,预计在预测期内对电动车电池材料的需求将大幅增加。

英国电动汽车电池材料产业概况

英国电动车电池材料市场已减半。主要参与企业(排名不分先后)包括住友化学、BASF、阿科玛、索尔维和优美科。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 至2029年市场规模及需求预测(单位:十亿美元)

- 最新趋势和发展

- 政府法规和措施

- 市场动态

- 促进因素

- 电动车销量成长

- 政府扶持措施及措施

- 抑制因素

- 对原料供应的依赖

- 促进因素

- 供应链分析

- PESTLE分析

- 投资分析

第五章市场区隔

- 电池类型

- 锂离子电池

- 铅酸电池

- 其他的

- 材料

- 正极

- 负极

- 电解

- 分隔符

- 其他的

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- Sumitomo Chemical Co., Ltd.

- BASF SE

- Arkema SA

- Solvay SA

- Umicore SA

- Mitsubishi Chemical Group Corporation

- Fiamm Energy Technology

- ENTEK International LLC

- Johnson Matthey

- Epsilon Adavnced Material

- 其他知名公司名单

- 市场排名/份额分析

第七章 市场机会及未来趋势

- 电池技术的进步

简介目录

Product Code: 50003567

The United Kingdom Electric Vehicle Battery Materials Market size is estimated at USD 1.03 billion in 2025, and is expected to reach USD 1.90 billion by 2030, at a CAGR of 13.06% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, growing electric vehicle (EV) sales and supportive government policies and regulations are expected to drive the demand for electric vehicle battery materials during the forecast period.

- On the other hand, the lack of raw material reserves can significantly restrain the growth of the electric vehicle battery materials market.

- Nevertheless, technological advancements in batteries like higher energy density, faster charging times, improved safety, and longer lifespan are expected to create significant opportunities for electric vehicle battery materials market players in the near future.

United Kingdom Electric Vehicle Battery Materials Market Trends

Growing Electric Vehicle (EVs) Sales Drives the Market

- In the United Kingdom (UK), rising electric vehicle (EV) sales are driving up the demand for EV battery materials. As the country embraces electric vehicles, the need for key battery components like lithium, cobalt, nickel, and graphite is surging. This heightened demand is not only stimulating local production but also attracting investments, thereby strengthening the UK's battery material supply chain.

- The UK is making a concerted shift towards clean energy, with electric vehicles taking center stage. Over recent years, EV sales in the region have seen exponential growth. For instance, the International Energy Agency (IEA) reported that in 2023, the UK sold 450,000 electric vehicles, marking a 21.62% increase from 2022. With the UK government launching several initiatives and projects, EV sales are projected to soar, consequently driving up the demand for battery materials.

- The UK government is actively nurturing the EV market through subsidies, tax incentives, and stringent emission regulations. These initiatives not only support the battery material sector but also elevate the nationwide demand for EVs. With ambitious targets set, the government envisions a fourfold surge in EV sales in the near future.

- As a testament to its commitment, the UK rolled out a Zero-Emission Vehicle (ZEV) mandate in 2023. This mandate stipulates that by 2030, 80% of new cars and 70% of new vans should be zero-emission, achieving a complete transition by 2035. Additionally, the sale of new petrol and diesel vehicles will halt by 2030, with all new vehicles required to be zero-emission by 2035. Such measures are set to accelerate both EV production and the demand for battery materials in the coming years.

- Furthermore, the UK's competitive EV landscape is driving innovations in battery technology. Local firms and research entities are investing in advanced materials, targeting improved energy density, longevity, and safety. Collaborations among major regional players aim to develop cutting-edge battery solutions, signaling a robust demand for EV batteries in the coming years.

- For instance, in January 2024, Microsoft, in partnership with the Pacific Northwest National Laboratory (PNNL) under the US Department of Energy, introduced a revolutionary material. This discovery, made using a combination of artificial intelligence (AI) and supercomputing, could reduce lithium consumption in batteries by an impressive 70%. Researchers also emphasize its potential to significantly enhance battery efficiency, particularly for electric vehicles (EVs) and related domains. Such advancements are poised to boost the demand for sophisticated EV batteries and, in turn, elevate the need for battery materials in the region.

- Given these developments, it's clear that the UK's initiatives and projects are set to not only bolster EV demand but also substantially increase the need for EV battery materials in the foreseeable future.

Lithium-Ion Battery Type Dominate the Market

- The growing production of lithium-ion batteries for electric vehicles (EVs) has significantly influenced the battery materials market. This surge in lithium-ion battery manufacturing has driven up the demand for lithium, with its discovery in various regions directly impacting raw material costs.

- Key market players, recognizing this trend, are ramping up investments in lithium reserves and R&D endeavors. Their goal is to bolster lithium-ion battery production and meet the escalating demand for battery raw materials. As new reserves are discovered, prices for lithium-ion batteries are notably declining.

- For instance, in 2023, battery prices dropped significantly to USD 139/kWh, marking a 13% decrease. With ongoing technological advancements and manufacturing efficiencies, experts predict prices could dip to USD 113/kWh by 2025 and plummet further to USD 80/kWh by 2030.

- Governments in the United Kingdom are actively promoting lithium-ion battery production for electric vehicles, driven by rising environmental concerns. With a strong focus on net-zero carbon emission targets, the government has launched numerous projects to boost lithium-ion battery production, aiming to meet the region's growing EV demand.

- In May 2023, Tata Motors, the owner of Jaguar Land Rover, announced plans for a state-of-the-art electric car battery plant in Somerset, southwest England, with investments reaching billions. Such strategic moves are set to accelerate the adoption of lithium-ion batteries as a pivotal clean energy source, amplifying the demand for battery materials in the foreseeable future.

- In recent years, the UK has been leading the charge in developing advanced battery recycling technologies for lithium-ion batteries. Companies and research institutions are innovating efficient methods to recover valuable materials like lithium, cobalt, and nickel from used batteries.

- In March 2024, Altilium, a UK company specializing in sustainable battery waste recycling, announced a collaboration with Nissan. This partnership aims to implement advanced recycling technologies, targeting a reduction in the carbon footprint of new UK-made batteries and a decrease in reliance on imported raw materials. This initiative, part of the Advanced Propulsion Centre's (APC) GBP 30 million (USD 38 million) project, saw Altilium securing a notable grant of GBP 15 million (USD 19 million). Such initiatives not only accelerate the production of lithium-ion raw materials but also bolster the future production of EV battery materials.

- Given these advancements and initiatives, a significant increase in the demand for EV battery materials is anticipated during the forecast period.

United Kingdom Electric Vehicle Battery Materials Industry Overview

United Kingdom's electric vehicle battery materials market is semi-fragmented. Some key players (not in particular order) are Sumitomo Chemical Co., Ltd., BASF SE, Arkema SA, Solvay SA, Umicore SA, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD billion, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Electric Vehicle Sales

- 4.5.1.2 Supportive Government Policies and Regulations

- 4.5.2 Restraints

- 4.5.2.1 Dependence on Raw Material Supply

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE Analysis

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion Battery

- 5.1.2 Lead-Acid Battery

- 5.1.3 Others

- 5.2 Material

- 5.2.1 Cathode

- 5.2.2 Anode

- 5.2.3 Electrolyte

- 5.2.4 Separator

- 5.2.5 Others

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Sumitomo Chemical Co., Ltd.

- 6.3.2 BASF SE

- 6.3.3 Arkema SA

- 6.3.4 Solvay SA

- 6.3.5 Umicore SA

- 6.3.6 Mitsubishi Chemical Group Corporation

- 6.3.7 Fiamm Energy Technology

- 6.3.8 ENTEK International LLC

- 6.3.9 Johnson Matthey

- 6.3.10 Epsilon Adavnced Material

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking/ Share Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Advancements in Battery Technology

02-2729-4219

+886-2-2729-4219